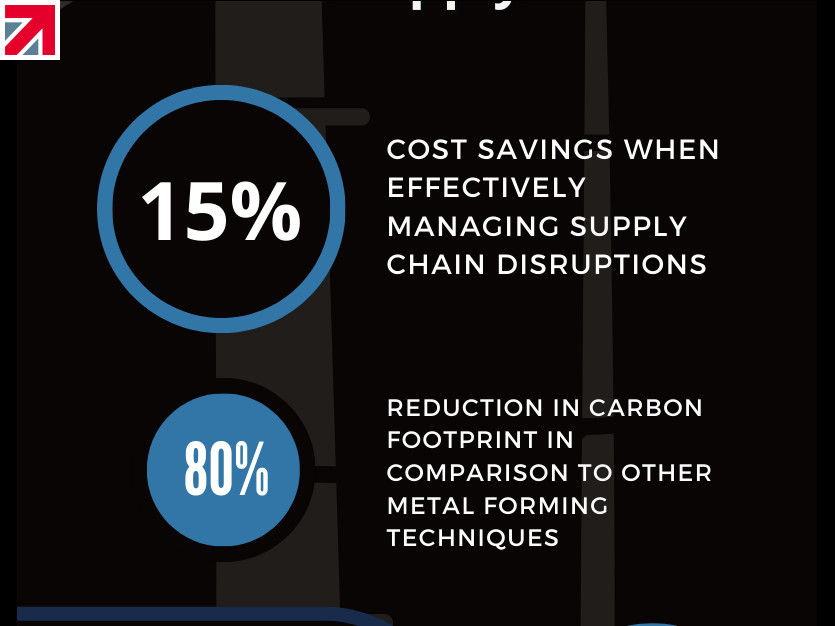

Unprecedented challenges are shaping the oil and gas sector, even as we write this blog. Factors including Geopolitical instability, environmental issues, and supply chain disruptions are redefining operations. Businesses in this industry are now feeling the pressure to adapt and innovate. All the while aiming to deliver high-quality products and services, meeting customer needs alongside these challenges. Elson (2023) suggests that managing supply chain risks allows Oil and Gas firms to reduce costs by 15% while sustaining growth.

Excell Metal Spinning acknowledges the challenges the Oil and Gas industry faces. Our services are tailored to helping businesses overcome these challenges with high-quality, reliable components. And in this post, we explore how metal spinning can provide solutions to many of the challenges the industry faces. We will discuss risk mitigation using metal spinning amid environmental, geopolitical and supply chain issues. Whether you’re a business owner or an industry professional, this blog post will provide valuable insights on metal spinning in the oil and gas industry. Let’s begin!

Metal Spinning: Oil & Gas Environmental Concerns

The oil and gas industry faces mounting pressure to lessen its environmental impact and meet stricter regulations. Notable environmental concerns for the industry include:

Greenhouse Gas Emissions;

- Greenhouse gas emissions: Reports from the IEA (2023) indicate that the oil and gas industry is responsible for about 15% of global greenhouse gas emissions, which contribute to climate change and its adverse effects. This is the equivalent of 5.1 billion tonnes of greenhouse gas emissions.

Air Pollution;

- Various pollutants are emitted such as nitrogen oxides, sulphur dioxide, volatile organic compounds, and particulate matter, which affect air quality and human health.

Water Pollution;

- The industry uses large amounts of water for extraction, processing, and refining, which can result in water contamination and depletion. Oil spills, leaks, and wastewater disposal can also harm aquatic ecosystems and biodiversity.

"How does Metal Spinning address the environmental concerns of the oil and gas industry?"

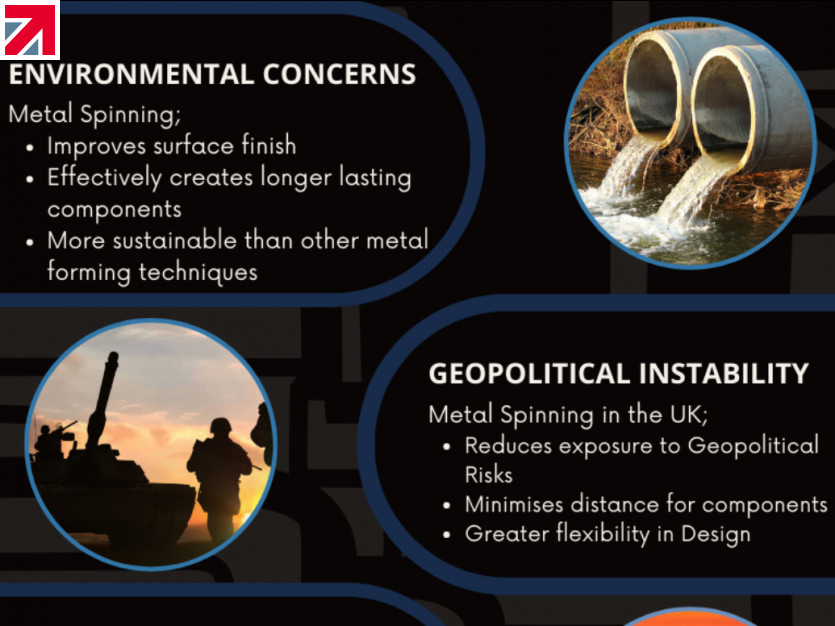

Metal spinning services can help the oil and gas industry reduce its environmental impact. It does this by providing high-quality, cost-effective, and sustainable metal parts for various applications. Opting for metal spinning over other metal forming techniques can be significantly advantageous. Especially regarding cost and reducing carbon footprint. Here’s how;

- Metal spinning can reduce greenhouse gas emissions by forming metal parts without removing material. This means less material waste and energy consumption compared to other metal forming techniques. Furthermore, it can also enable the use of recycled or renewable materials, such as aluminium or copper. Both of which have lower carbon footprints than steel or iron (Pittman, 2016). According to Roche Industry, metal spinning is even claimed to reduce carbon footprint by as much as 80%. This is in comparison to other metal forming techniques (Robin, 2021).

- Surface finish and dimensional accuracy of the metal parts are also greatly improved when opting for Metal Spinning. This means less friction and wear and tear on the metal parts, thus reducing the emission of pollutants from equipment.

- Metal spinning services can also produce high-strength, high-temperature, and corrosion-resistant metal parts that can withstand harsh environments and pressures. This means less maintenance, repair, and replacement of the metal parts, prevent oil spills, leaks, and corrosion from the equipment. Thus resulting in less water contamination and damage to aquatic ecosystems and biodiversity.

Metal Spinning: Oil & Gas - Geopolitical Instability

The oil and gas industry is highly exposed to geopolitical instability. Subsequently affecting the supply and demand of oil and gas components in the global market. Geopolitical instability refers to the uncertainty and risk caused by political, social, economic, and environmental factors. These factors influence the decisions and actions of governments, corporations, and individuals involved in the oil and gas industry. Some of the geopolitical factors that can affect the oil and gas industry are:

Conflicts and Wars;

- Conflicts and wars can disrupt the production, transportation, and distribution of oil and gas components in the affected regions, as well as create security threats for the personnel and assets of the oil and gas companies. Wars can also affect the demand for oil and gas components, as they can reduce economic activity, trade, and consumption.

Sanctions and Embargoes;

- Sanctions and embargoes are political measures that restrict or prohibit the trade or financial transactions with a certain country or entity. They can affect the supply and demand of oil and gas components, as they can limit the access to certain markets, resources, technologies, or financing.

Regulations and Policies;

- Regulations and policies are legal rules and guidelines that govern the operations and activities of the oil and gas industry. These affect the supply and demand of oil and gas, as they can set standards, requirements, incentives, or penalties for the production, consumption, or emission of oil and gas and associated components.

"How can metal spinning services in the UK help mitigate risks associated with Geopolitical Instability?"

Metal spinning services in the UK can help mitigate risks associated associated with geopolitical instability. It can do so by providing high-quality, cost-effective, and flexible metal parts for various applications in the industry. UK Metal spinning services can offer the following benefits:

- They can help you adapt to changing market conditions and customer demands through customisation. You can customise your products according to different specifications, standards, and regulations. UK-based suppliers are known for their ability to adapt to changing market conditions and customer needs. They are also known for their ability to provide customized solutions that meet specific customer requirements (Made in Britain, 2023). Metal spinning, in this instance, can create complex shapes with minimal material waste. Moreover, it allows for flexible design changes and modifications.

- Metal Spinning can help ensure your products are reliable and durable by producing high-strength, high-temperature, and corrosion-resistant metal components. Especially important for withstanding harsh environments and pressures. Furthermore, metal spinning improves the surface finish and dimensional accuracy of the metal parts. This reduces friction, wear, tear, maintenance, repair and in particular, replacement costs. In addition, this forming process also produces metal parts that are compatible with various coatings or treatments for performance enhancement.

- Metal spinning services in the UK can help you demonstrate your commitment to environmental sustainability. It does so by reducing your material waste and energy consumption by forming metal parts without removing material. Metal spinning also enables you to use recycled or renewable materials such as aluminium or copper. Both of which have lower carbon footprints than steel or iron.

Choosing metal spinning services in the UK for your oil and gas projects, can reduce your exposure to geopolitical risks. At Excell Metal Spinning Ltd, we have decades of experience in providing metal spinning services for the oil and gas industry. We have the expertise, equipment, in addition to quality standards to meet your specific requirements. Moreover, we are ISO 9001 certified, which means we fulfil the highest quality standards available in our industry.

Metal Spinning: Oil & Gas Supply Chain Disruptions

The oil and gas industry relies on a complex and interconnected supply chain that spans across the globe, involving multiple stakeholders. These include producers, suppliers, contractors, transporters, distributors, and customers. The supply chain is essential for ensuring the availability, quality, and affordability of oil and gas products and services. However, the supply chain is also vulnerable to various disruptions that can affect its performance, efficiency, and reliability. Some of the major risks of supply chain disruptions in the oil and gas industry are:

Natural Disasters;

- Natural disasters, such as earthquakes, hurricanes, floods, or wildfires, can damage or destroy the infrastructure, equipment, or facilities involved in the production, transportation, or distribution of oil and gas. Subsequently disrupting the communication, power, or water supply that are necessary for the operation of the supply chain.

Geopolitical Conflicts;

- Geopolitical conflicts as we have highlighted, can disrupt the supply or demand of oil and gas in certain regions or markets. Thus creating security threats or regulatory uncertainties for the stakeholders involved in the supply chain. For example, the war in Ukraine in 2023 caused a major disruption in the European gas market, (Moritsch & Mayor, 2022).

Cyberattacks;

- Cyberattacks are malicious attempts to access, damage, or disrupt the information systems or networks that support the operation of the supply chain. Therefore compromising the data integrity, confidentiality, or availability of the supply chain stakeholders.

"How can metal spinning services in the UK help mitigate risks associated with Supply Chain disruptions?"

Metal spinning services can help mitigate risks associated with supply chain disruptions by providing high-quality, cost-effective, and flexible metal parts for various applications in the oil and gas industry. Metal spinning services can offer the following benefits:

- Resilience: Metal spinning services can help you build resilience in your supply chain by reducing your dependence on external suppliers or contractors. Metal spinning requires less tooling and equipment than other metal forming techniques. This means you can produce your own metal parts in-house or locally with less lead time and storage space.

- Quality: Metal spinning services can help you ensure quality in your supply chain by producing high-strength, high-temperature, and corrosion-resistant metal parts that can withstand harsh environments and pressures. Metal spinning also produces metal parts that are compatible with various coatings or treatments that can enhance their performance or appearance.

- Flexibility: Metal spinning services can help you achieve flexibility in your supply chain by allowing you to customise your products according to different specifications, standards, and regulations.

Conclusion

Metal spinning is one of the innovations that can help the oil and gas industry achieve resilience, efficiency, and innovation in their supply chains. By choosing metal spinning services for your oil and gas projects, you can not only improve your performance and profitability but also demonstrate your commitment to environmental sustainability and social responsibility.

In this blog, we have highlighted the many benefits Metal Spinning brings to the table in three areas of concern for the Oil and Gas industry. Leveraging the power of Metal Spinning within your supply chain is a sure way of adapting and innovating under wider economic pressures. And we're here to help!

For all Metal Spinning enquiries, contact us via email today or alternatively fill out our contact us form. Our team of friendly and helpful staff are on hand to assist you with your oil and gas component needs!

Citations

Elson, N. et al. (2023) How oil and gas companies can secure supply-chain resilience, McKinsey & Company. Available at: https://www.mckinsey.com/industries/oil-and-gas/our-insights/how-oil-and-gas-companies-can-secure-supply-chain-resilience#/ (Accessed: 31 August 2023).

IEA (2023), Emissions from Oil and Gas Operations in Net Zero Transitions, IEA, Paris https://www.iea.org/reports/emissions-from-oil-and-gas-operations-in-net-zero-transitions, License: CC BY 4.0

Made in Britain (2023) Spinning towards sustainability: Excell’s green journey, Made in Britain. Available at: https://www.madeinbritain.org/news/spinning-towards-sustainability-excells-green-journey (Accessed: 04 September 2023).

Moritsch, S. and Mayor, R. (2022) Top risks facing the oil and gas industry in 2022 - and what you can do about it, KPMG. Available at: https://kpmg.com/xx/en/home/insights/2022/04/top-risks-facing-the-oil-and-gas-industry-in-2022.html (Accessed: 31 August 2023).

Pittman, K. (2016) The facts behind metal spinning and hydroforming, Engineering.com. Available at: https://www.engineering.com/story/the-facts-behind-metal-spinning-and-hydroforming (Accessed: 31 August 2023).

Pro Gas Services (2021) Geopolitics and the oil and gas industry, Pro Gas, LLC-Products & Services. Available at: https://www.progasllc.com/geopolitics-and-the-oil-and-gas-industry/ (Accessed: 31 August 2023).

Robin (2021) Handbook: The ultimate guide to metal spinning, Roche Industry. Available at: https://www.rocheindustry.com/metal-spinning/ (Accessed: 31 August 2023).

Find out more about Excell Metal Spinning Ltd on their member profile page here

Member-created content 2 years ago | From members