Here at Qualkem we are always looking for new ways to offer innovative solutions to our clients. When manufacturing aficionado, Steve Pickett, joined the team 6 months ago we quickly identified an opportunity to deliver a brand new Qualkem service – tube filling and labelling.

Steve talks to us about what drives his passion for manufacturing and his vision for Qualkem when it comes to providing this complete new service that is ideal for small and start-up businesses.

As part of the Qualkem team, Steve is Operations Manager and is responsible for ensuring the manufacturing side of the business runs seamlessly. Steve’s motto is “done right first time – every time” and our operations at Qualkem have definitely benefitted from Steve’s ethics and extensive experience.

In this news feed, Steve reflects on how his previous experience stood him in good stead for his role at Qualkem, and how this role and the team at Qualkem support and enables him to drive innovation and growth.

Steve left school at 16 and secured an apprenticeship at Crewe Works, a British railway engineering facility, and it was there that his passion for engineering developed. Starting from the ground up, Steve worked on building and repairing trains, including travelling around Britain ensuring machines in some of the world’s leading organisations such as Shell were operating efficiently, this included high voltage machines and balancing rotating equipment.

Steve stayed at Crewe Works for 9 years, and in theory Steve can take a locomotive apart and put it back together – although there is not much need for that at Qualkem! However, his depth of engineering skills and enquiring mind are a key part of Steve’s skill set.

Steve’s next roles held at Fryma, Bosch, Eiger Torrence and Lubepack bring extensive experience in sales, manufacturing and operations. Steve travelled the world fixing, maintaining and educating teams on manufacturing and machines, including learning about cosmetics and emulsions, working with beauty brands such as Amelia Knight, Elizabeth Arden, Boots and Rimell.

The team at Qualkem had known Steve for several years, and when the right opportunity arose, Steve was approached to work as Operations Manager, adding his 35 years of experience to the business.

Steve chats to us and explains his role at Qualkem further…

“I am excited to be working with Qualkem and am passionate about what we can achieve as a team. There is so much potential and I am excited to be launching our new tube filling service.

Tubes?

I love the potential and opportunity of tube filling at Qualkem, we can fill any lotion, creams, pastes and gels, which lends itself to a range of products including beauty products such as moisturisers, cleansers, hand creams, serums – basically flexible squeeze tubes.

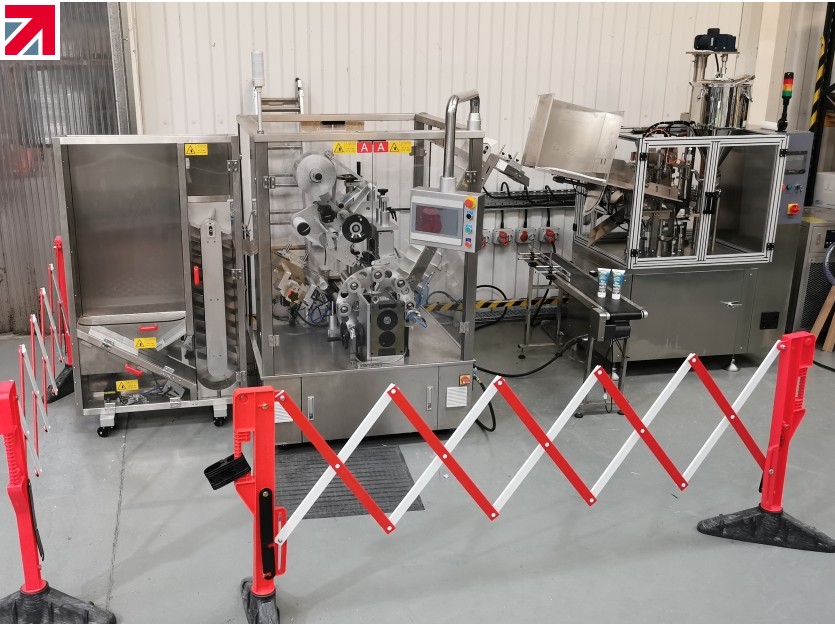

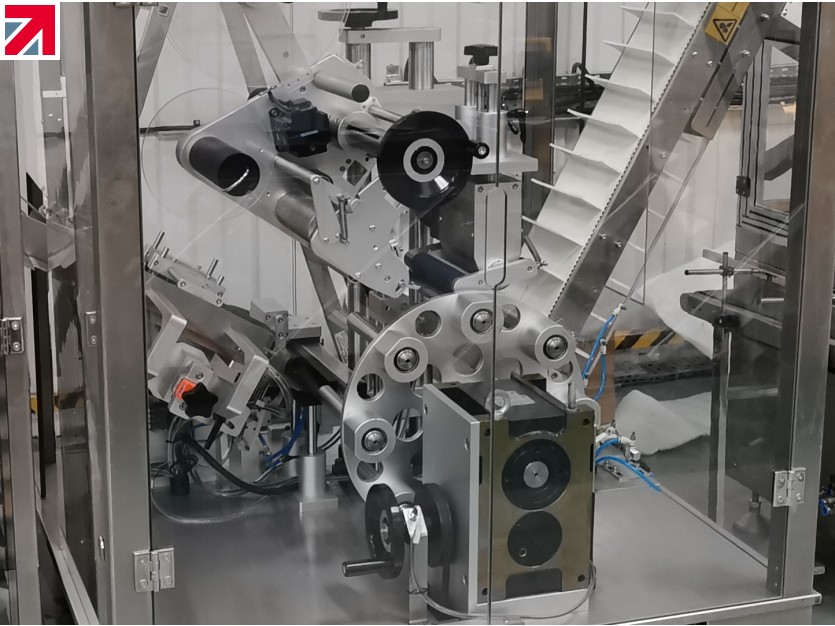

Qualkem have recently invested in 2 new tube machines, one is a tube labelling machine and one is a tube filling machine, that can fill any 35 mm, 40mm, 50mm diameter tubes.

Our machines are fully automated, ensuring the quality of the tube reflects the quality of the product.

Our ideal client would be a small, start-up business who want small runs and a quick turnaround. I’ve always felt frustration over long lead times which can be over 16 weeks, and we can easily fill up to 10,000 tubes in a day ensuring that we can meet customers’ demands.

We are keen to partner like minded business and sustainably grow together.

Tell us more….

There are many benefits of working with us, including our sustainability values, our fast turnaround time and flexibility, our quality standards and the fact that there is no MOQ

What do you mean by no MOQ?

Qualkem does not have a minimum order quantity, which means that we can work with smaller organisations, exciting start ups or on more bespoke ranges for larger brands.

What do you mean by sustainability?

Qualkem is committed to reducing the demand on virgin plastics and doing its bit for the planet and society. we offer a range of completely sustainable packaging solutions from upto 100% PCR tubes, upto 85% recycled PE labels and 85% recycled cardboard packaging. All in all, our finished product is both made from recycled materials, but also recyclable.

Why Qualkem?

We offer a complete, personal service that is totally trustworthy and bespoke to our customer. We make sure our customers get the right product, in the right place, at the right time.

We strive to always deliver better, using innovation and our forward-thinking expertise to respond to challenges and overcome barriers. Our standards adhere to ISO 9001, quality system that we pass with flying colours.

Our ethos as a business makes me proud to work at Qualkem. We have a saying ‘from our family to yours’ and it really does feel that way. Qualkem is a family business so we work with out customers rather than for our customers – our customers and clients are part of the Qualkem family and an extension of our business.

We always want our customers to have a positive experience when they work with us. We reflect their values treat our customers product with respect and care as if it were our own.

We are also hugely proud to champion chemical manufacturing & contract packing in Britain

Find out more about Qualkem Limited on their member profile page here

Member-created content 3 years ago | From members