A leading global provider of approved maintenance, repair and overhaul services, based in Aberdeen, Scotland have been working with SurfacePrep UK. The services they carry out are on gas generators used in power generation for the oil and gas industry.

They are well known for their work throughout the industry and when they developed a need to refurbish their blast cabinet they contacted SurfacePrep UK, to work with them on the project.

SurfacePrep UK have a long-standing working relationship with the company over several years. They already have an ongoing comprehensive servicing and maintenance plan, as well as buying their required spare parts from SurfacePrep UK.

So, when their blast cabinet needed refurbishment they knew that working with SurfacePrep UK they would achieve a high quality solution and exemplary workmanship.

WHY CHOOSE REFURBISHMENT?

Prolonging the lifespan of a blast cabinet can be beneficial. Like any large item of machinery, it can be better to refurbish the existing product rather than buying new and simply scrapping the old one.

In a time when businesses are looking at how they can contribute to a circular economy and focussing on their environmental concerns, refurbishment can help.

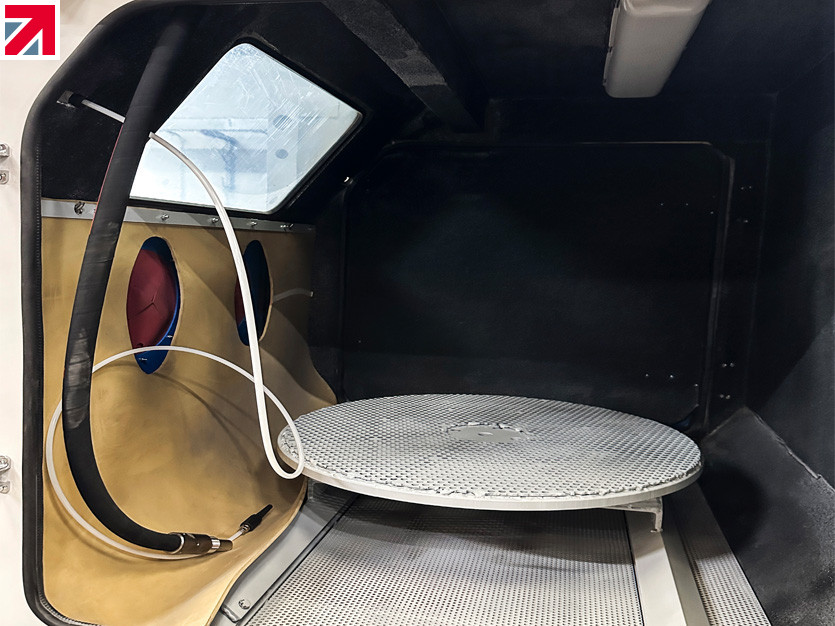

Having a cabinet undergo refurbishment means it is diverted from landfill. When refurbishing a cabinet, it can be fully

refurbished with all mechanical parts replaced and the aesthetics upgraded. Or a specified refurbishment can take place where a company can define what parts etc need refurbishing in agreement with the SurfacePrep UK team.

“We have a long-standing relationship with your Scottish Engineer, John Anderson. Due to the comprehensive servicing and maintenance plan, we rarely have any equipment problems between service visits. Complete refurbishment and overhaul of the equipment will also help reduce this further.”

PETER FOWLIE

Maintenance Supervisor

PLANNING THE REFURBISHMENT

Before any refurbishment work is started, the process must be planned out. This activity involves meetings to identify the key issues and problems with the machine.

In the case of this particular company the machinery was looked at to see how it could be modified to make it more user friendly for the operator. In this instance an auto dump system was added to the feed valve assembly, essentially speeding up and making the media change more efficient when using the cabinet.

Looking back on the project this was a game changer for the operators and maintenance on the site.

"SurfacePrep UK have been working with the company for several years, so when they approached us to discuss what options they had regarding replacing or refurbishing their blasting cabinets, we had to ensure their needs and requirements were understood and their expectations were fully met. What was their timescale, what was their budget and did they require any upgrades to the equipment."

ANDY PEART

Sales and Service Director, SurfacePrep UK

BUILDING CUSTOMER RELATIONSHIPS

At SurfacePrep UK, we pride ourselves on our customer relationships. Building long lasting customer relationships are important us as they are vital for business development.

For the company their relationships with members of our team was a huge contributing factor to them choosing us for their refurbishment project. They trusted in the company’s ability and professionalism to deal with the venture and deliver a successful cabinet refurbishment.

Having completed a successful refurbishment project with the company, they are looking to continue and strengthen their relationship. Making SurfacePrep UK their total service solution provider for all their blasting requirements.

SurfacePrep UK have a long-standing working relationship with the company over several years. They already have an ongoing comprehensive servicing and maintenance plan, as well as buying their required spare parts from SurfacePrep UK.

Find out more about SurfacePrep UK on their member profile page here

Member-created content 1 year ago | From members