Steam systems are not only energy intensive, but they can be a complex mix of new and old infrastructure. This means that many systems and components are difficult to gain access to. As a result, engineers or plant managers do not have day to day visibility on their systems. With that in mind, DCO Systems set out to build, develop and improve maintenance-free, remote steam trap monitoring solutions. A key goal was to eliminate the reliance on batteries because difficult to access places are not somewhere you want to be regularly changing batteries. The result was a monitoring system powered with energy harvesting technology that provided always-on monitoring. One box ticked and one large problem solved! Yet after assessing many of the common layouts encountered on client sites, another requirement emerged and has now led DCO Systems to usher in a new Easy Steam Trap Monitor generation.

What is the current challenge

Because of the intricacies and complexity of steam systems, it can be difficult to fit a monitoring solution, even a self-contained one, onto the pipework. Particularly in drip and line applications the space between components, unions and insulation is restricted and the free runs of pipe needed for installation become an issue. Notably, some wireless monitoring solutions on the market have components that can require as much as 230mm (9in.) of free pipe for fitting. Unfortunately, the area around the steam trap is usually crowded with other components and demands greater flexibility. That's why DCO are launching a new model that is possibly the smallest on the market yet.

How is this solving the problem

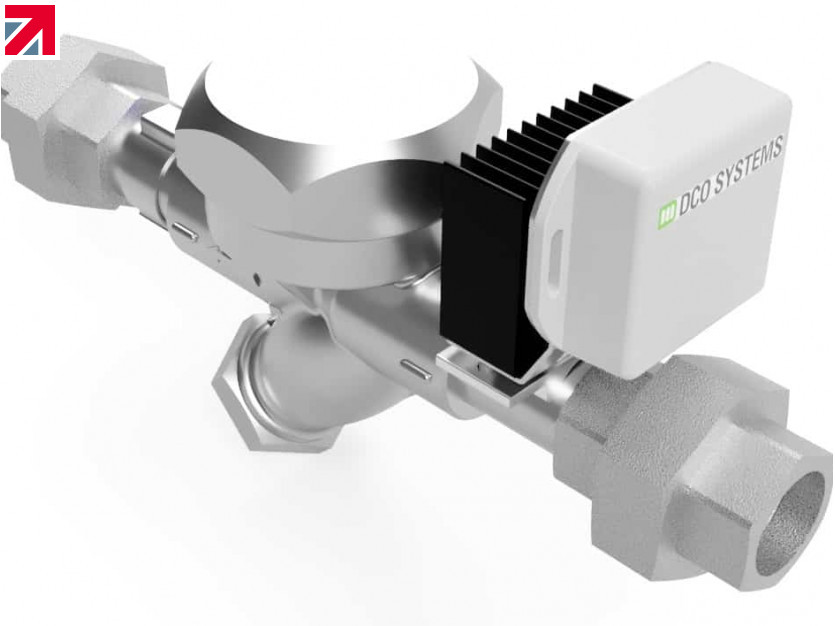

The smaller Easy STM model requires just 25mm of free space for fitting on pipework. It consists of two components and comes with a multi-fit interface to fit both DN15 (1/2”) and DN20 (3/4”) pipework. A single clip-on harvesting and sensing module contains the entire assembly, only one extra wired probe is required to sense the condensate side of the steam trap. All components can now fit into less than a 25mm (1”) space and can much more easily be fitted around existing flanges, unions, and insulation jackets. The new model is designed for drip type or line type lower value traps and provides thermal-only monitoring. Two immediate benefits include the ability to significantly simplify installation and reduce costs on lower value traps.

What can you do with it

The phrase ‘good things come in small packages’ certainly rings true for the new, smaller model. And an optional upgrade includes acoustic sensing. This allows the sensor to listen to the surrounding environment and can detect leaks to adjacent equipment, such as isolation or control values. Indicators on the unit provide visibility to the engineer of monitor and trap status. But even when an engineer is not present, all traps are monitored remotely, and data can be sent to a dashboard providing analytics, alerts, and tangible insights. DCO’s new Easy Steam Trap Monitoring model will be available for purchase beginning in March 2023. To learn more and register your interest, contact DCO Systems or email info@dcosystems.co.uk.

Find out more about DCO Systems Limited on their member profile page here

Member-created content 2 years ago | From members