Summary

Cross Engineering Swansea Ltd are truly driven by their mission “to keep industry moving while meeting every client’s needs and requirements”. Cross Engineering’s precision engineering workshop provides a full range of equipment to service local and national businesses in a wide range of industries.

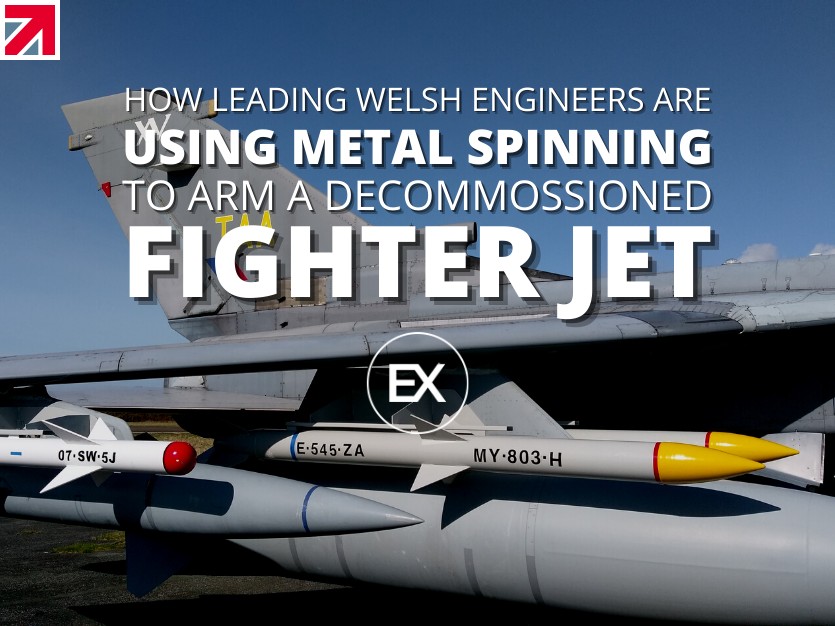

What really resonates with their existing audience is their level of expertise, with over 50 years specializing in jigs, fixtures and special purpose machinery with a fabrication department producing precision pieces from a large assortment of materials. Cross Engineering Swansea Ltd. Approached us for a number of nose cones that were to be used on dummy missiles for a decommissioned fighter jet.

Here’s how we helped bring Cross Engineering’s project to life, delivering high quality components, and all the while following through on their mission.

Cross Engineering Swansea Ltd.

We got to speak with Andrew Phillips, works Manager at Cross Engineering Swansea Ltd. Andrew completed his engineering apprenticeship at Dowty Rotol in Gloucester in 1983 and then moved back to Swansea where he was brought up. He subsequently worked at a number of local sub contract engineering machine shops before starting his employment at Cross Engineering in July 1988. There he spent two years on the shop floor before becoming workshop foreman in 1990. He was later promoted to his current role as works manager in 2014.

“Cross Engineering Swansea has been established for over 50 years, specializing in jigs, fixtures and special purpose machine builds and with our fabrication department producing high quality work in stainless steel, mild steel and aluminium.

We offer a full engineering service to all local and national industry and with the introduction of Abrasive waterjet cutting technology, we have added another invaluable service that will surely benefit customers old and new.

Our precision engineering workshop provides a full range of equipment required to service local and national Business in a wide range of industries from steel making, pharmaceutical, food, petro-chemical as well as the general and structural sectors.

We pride ourselves in offering each customer personal attention regardless of the size of the project” – Andrew Phillips, Works Manager at Cross Engineering Swansea Ltd.

Cross Engineering over its 50 year history has successfully undertaken design and manufacturing projects for a vast array of industries, and their ability to deal with tasks quickly and efficiently is clear to see within the many projects they handle. You can learn about their work at www.crossengineering.co.uk/

The Problem

Andrew revealed “we were approached by an individual who had purchased a decommissioned fighter jet as a show piece. He asked us to manufacture dummy missiles in a couple of different configurations.

They needed to be as light as possible for ease of handling and fitting. We could only manufacture the nose cones from solid aluminium which was too heavy for the project, and a decision was made to source a metal spun alternative from Excell Metal Spinning Ltd.”

The ‘Dealbreaker’

During the initial stages of the project, Cross Engineering began researching a number of alternative organisations that could potentially be of service for their requirements.

“We looked at a number of different spinning companies before choosing Excell Metal Spinning Ltd. Your testimonials and cost were preferable over any other we spoke to”

The dealbreaker was made when Cross Engineering was able to identify a cheaper alternative within our services in comparison to other Metal Spinners. Andrew also highlighted the positive reputation Excell Metal Spinning ltd. has within industry and explained that there were no issues during the purchasing process “what so ever”.

The Solution and Results

After discussions were made on the components, and technical drawings highlighting the dimensions and quality requirements were submitted, we made the decision to hand craft the components given the scale of the project.

Two variations of spinnings were required with a set of four 8” and 4” cones required for the dummy missiles. There are many advantages associated with hand spinning. The operator is able to form the cones through precise motion rather than brute force. And given the requirements and the use of sheet aluminium, it was ideally suited for hand crafted processes.

We knew cost would also play an important factor within this project, and given the scale of the project regarding quantity, we felt it was far more economic to hand craft the aluminium cones and save Cross Engineering money further down the line.

The project had a positive outcome. Andrew explained how our “spinning services helped enormously with the weight reduction of the part. Your service helped us complete the job on time and within specification”

Final Message

We would like to wish Andrew Phillips and the team at Cross Engineering Swansea Ltd the very best in their future endeavours. Cross Engineering has survived some tough times through its history, especially during the recession, and has come through it stronger than ever. We understand it’s their intention to serve local and national industry for many years to come.

Cross Engineering are a testament to Quality British manufacturing and offer a prime example of the resilience British manufacturing is known for.

You can find Cross Engineering on LinkedIn for regular updates

- LinkedIn – Cross Engineering Swansea Ltd

Your Next Project

As a leading expert in the field of Metal Spinning, and the leading organization in the UK Metal Spinning Industry, Excell’s services have been widely sought after worldwide. With the vast skills and knowledge required, we can ensure quality products are delivered on time and to your requirements!

To get started on your next project with us, and to determine the best possible solution for your industry needs, you can fill out a Quotation Form. Our team are on hand ready to help you!

Find out more about Excell Metal Spinning Ltd on their member profile page here

Member-created content 4 years ago | From members