What is Lean Manufacturing?

Lean Manufacturing or sometimes known as lean production or simply, “lean”, is a production process that was introduced to the West in the 1980’s. It was a practice that was invented by Toyota, a Japanese Car Firm who developed a process to reduce waste within their business. Lean Manufacturing is simply a production practice that considers the expenditure of resources for any goal other than the creation of value for the end customer to be wasteful.

What are the benefits of Lean Manufacturing?

Adopting Lean processes offers many benefits for manufacturers across any sector ranging from reduced costs to improved service. The following are considered benefits of Lean Manufacturing;

Ø Improved customer services - helping deliver exactly what the customer wants and when they want it.

Ø Improved productivity – Increased production and value added service

Ø Innovation - Staff are fully involved which results in higher morale within the workplace and increased participation throughout the business

Ø Reduced waste - Lean allows for less transport, moving, waiting, space and physical waste within the business.

Ø Improved stock turns – less work in progress and inventory resulting in less capital tied up.

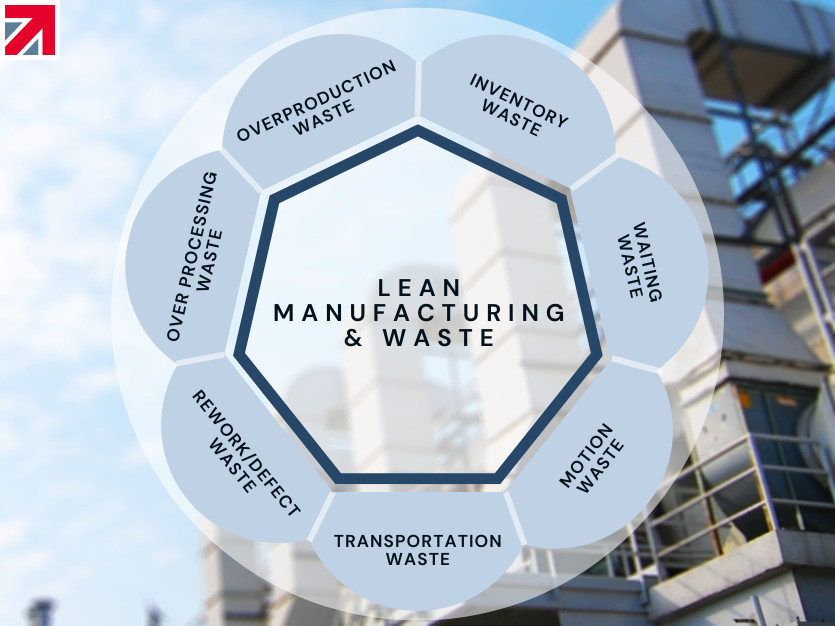

So what are the Seven wastes of Manufacturing?

1. Overproduction Waste

Overproduction waste is the result of producing products to soon or in greater quantities then the customer demanded. This is seen as the worst kind of waste and obscures the need for improvement. Not only is this waste the result of unnecessary production of products being produced too fast, but also the result of;

Ø Large batch sizes being produced

Ø Unreliable processes within the company/business

Ø Unstable schedules

Ø Unbalanced cells or departments

Ø The Company working to forecast or inaccurate information which is not the actual demand of the customer.

To avoid the unneeded waste of overproduction, balancing the supply with the demand needs to be taken into due consideration.

2. Inventory Waste

An indication of an unnecessary accumulation of inventory before or after a process, is the failure to achieve a continuous flow. It is therefore considered a waste in manufacturing. Excess inventory is a result of;

Ø A lack of balance within the work flow which forces inventory to build up during processes. Space is wasted as a result

Ø Large batch sizes being produced

Ø The failure to observe first in or out, stagnant material

Ø Incapable processes that are in place

Ø Long changeover time

Ø Not adhering to procedures

3. Waiting Waste

This kind of waste is the cause of people or parts that wait for a work cycle to be completed. It can also be the result of failure to successfully synchronize activities.

Waste of waiting is seen as any idle time produced when two interdependent processes (or processes that rely on each other) are not completely synchronized with one another. This results in delays due to waiting time or lower productivity due to long cycle times of machinery. Waiting can also be a result of poor man or machine coordination as well as long changeovers.

Unreliable processes or poor quality can be a big factor to this type of waste. In addition, the time required to perform rework due to rejected, poor quality products can also play a significant role in waiting.

4. Motion Waste

Motion waste is the unnecessary movement of people, parts or machines often associated with poor workflow layout. This often results in the transferring of parts from one place to the next requiring a larger distance to travel. Material reorientation is also a contributor of motion waste.

5. Transportation Waste

Transportation waste is the unnecessary movement of people or parts between processes and is also the result of material movement that is not directly associated with the value adding process.

Processes should be situated as close together as possible to avoid transport waste and allow for movement of material to flow from one process to the next without any significant delays. To fully tackle transportation waste, you must consider the factors that contribute to this waste. Excess transportation is caused by the following:

Ø Poor layout of departments

Ø Distance between layouts

Ø Lengthy and or complex material handling

Ø Large batch sizes

Ø Overproduction

Ø Multiple storage locations

6. Rework / Defect Waste

This type of waste is the result of a product not being manufactured correctly first time and so the process has to repeat itself or correct itself. This is mainly due to unclear operating procedures or specifications but can also be the result of:

Ø Inadequate training

Ø Shortage of skills

Ø Incapable processes

Ø Incapable suppliers

Ø Operator error

Ø Excessive stock

Ø transportation.

7. Over Processing Waste

This type of waste is the outcome of processing beyond the standard required by the customer, or putting more into the product(s) than is valued by the customer. This is due to the result of unnecessarily tight tolerances or cleaning/polishing beyond the level that is required.

The goal objective that should be kept considered during processes of product(s) is, to do only the level of processing to match that which is useful and strictly necessary. Over processing can be caused by no standardization of best techniques or unclear specification/ quality acceptance standards.

Conclusion

Knowledge of the 7 signs of waste in manufacturing will help identify improvements within your production process. By taking steps to reduce or eliminate areas of waste, manufacturers can benefit from improved lead times, reduced costs and improved customer service.

The long term gains arguably outweigh the short term costs, and will assist manufacturers to be much more competitive within their respective industries.

Tag us on social media with your thoughts on LEAN Manufacturing including #LEANExcell in your post. Is this something you implement within your business? What tangible benefits have you seen as a result of implementing LEAN in your production processes? Is there something we missed?

Find out more about Excell Metal Spinning Ltd on their member profile page here

Member-created content 3 years ago | From members