When planning a conveyor project, one of the first decisions to make is whether to work directly with a conveyor manufacturer or hire a systems integrator to manage the process. While both play valuable roles in the industry, many businesses are discovering that dealing directly with a manufacturer offers more control, transparency, and long-term value.

5 reasons to consider working directly with a conveyor manufacturer

1. Direct Access to Product Expertise

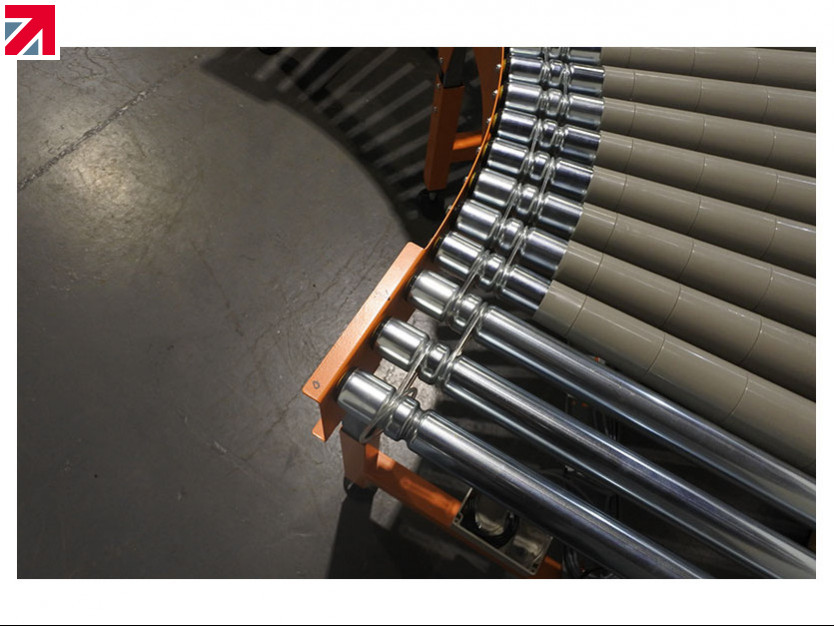

Manufacturers are deeply familiar with their own equipment — they’ve designed, engineered, and tested every component. When you go straight to the source, you’re speaking with experts who can advise on the best solution for your unique needs. Integrators often work with various third-party suppliers, which can dilute technical understanding or create compatibility issues.

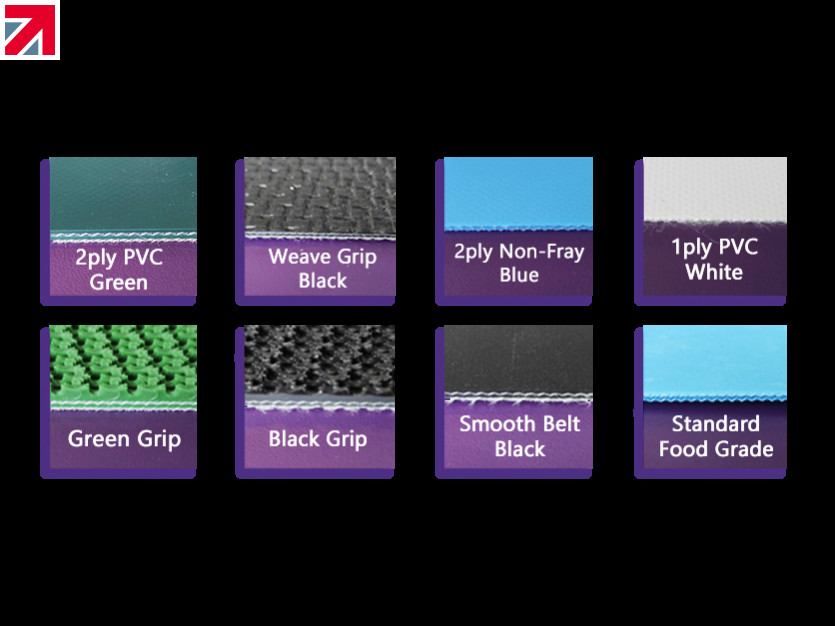

2. More Customisation, Built-In

Conveyor manufacturers typically offer bespoke systems tailored to the client’s operation. Whether you need a specific belt width, roller spacing, speed configuration, or frame design, a manufacturer can build it to spec. Integrators may be limited to off-the-shelf components from multiple vendors, which can restrict flexibility.

3. Improved Cost Transparency

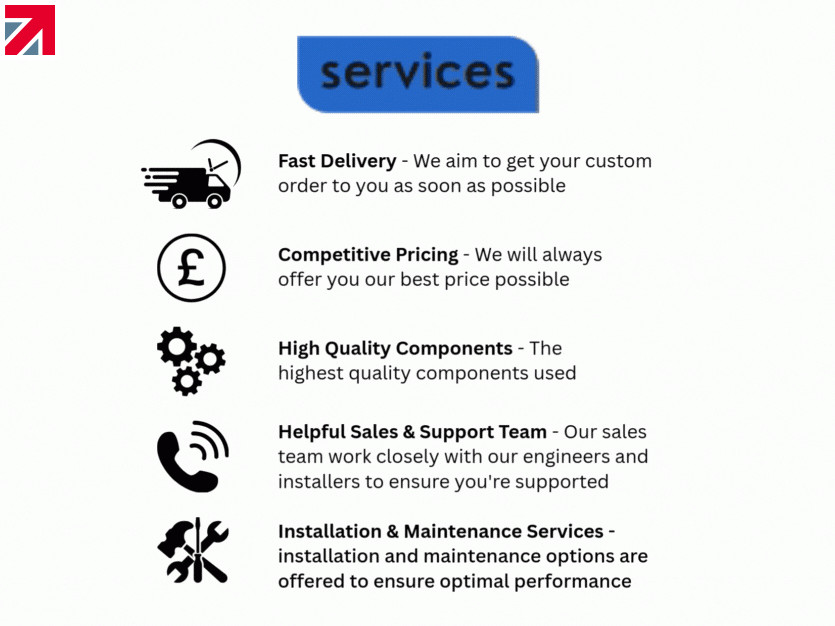

When you work with a conveyor manufacturer, pricing tends to be clearer and more straightforward. Integrators often add mark-ups for project management or margin on equipment they don’t make themselves. By cutting out the middleman, you can get a clearer view of where your budget is going — and often reduce costs.

4. Quicker Communication and Project Turnaround

Manufacturers handle everything in-house: design, build, testing, and sometimes even installation. This reduces lead times and makes communication much more efficient. With integrators, the chain of communication can become longer, especially when they’re relying on multiple external equipment providers.

5. Ongoing Support From the Original Equipment Builder

Perhaps the biggest benefit of going direct is long-term support. When an issue arises down the line or you need replacement parts, you’re already connected to the team that built your system. This continuity makes maintenance and upgrades easier, and support more reliable.

While integrators can offer value in highly complex, multi-vendor systems, for many operations, going straight to a trusted British conveyor manufacturer can simplify the process and lead to a better result.

Whether you're designing a new facility or upgrading your current setup, working directly with a manufacturer can save time, reduce cost, and give you more confidence in the solution you're investing in.

FAQ

What is the difference between a conveyor manufacturer and a systems integrator?

A manufacturer designs and builds conveyor systems in-house, while an integrator assembles complete systems using equipment from various manufacturers.

Is working with a conveyor manufacturer cheaper than using an integrator?

Often yes — going direct removes the middleman’s markup and simplifies project costs.

Can manufacturers still help with full system integration?

Many manufacturers can offer turnkey solutions or collaborate with trusted partners to provide end-to-end integration if required.

Our amazing team can design and build a full system including workstations / workbenches / packing stations and conveyors dedicated to your processing needs with countless accessories to add resulting in your entire production becoming faster and smoother.

📞 01482 363445

📧 sales@conveyorsystems.co.uk

Explore our websites for tailored solutions:

🌐 SpaceGuard.co.uk – Workplace Equipment

🌐 PackingTables.co.uk – Packing tables and Workbenches

🌐 ConveyorSystems.co.uk – Conveyor Solutions

🌐 CuttingTable.co.uk – Specialist Cutting Tables

Find out more about Spaceguard Ltd on their member profile page here

Member-created content 6 months ago | From members