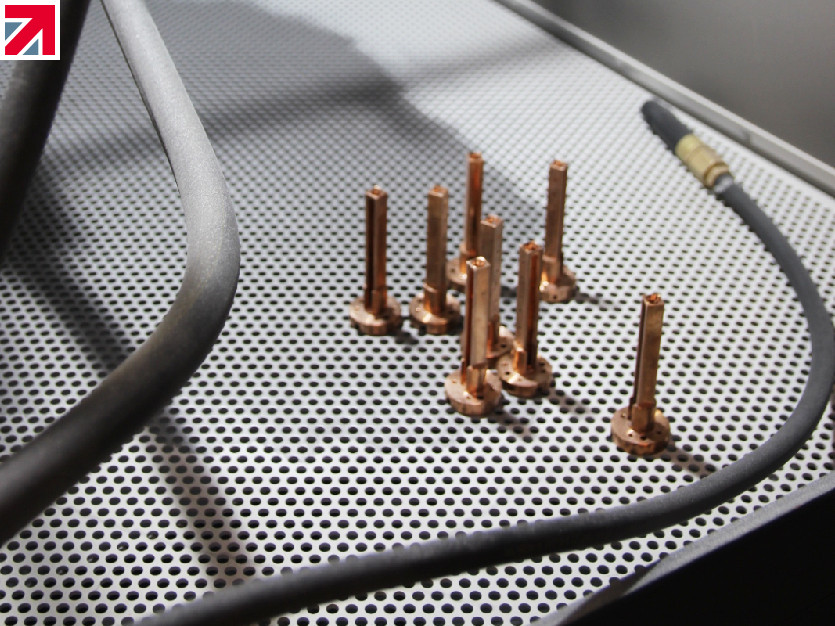

In manufacturing, achieving high-quality finishes on metal parts is essential for durability and aesthetic appeal. Shot blasting is a critical step in preparing metal forgings and castings, as it removes contaminants, smoothens rough edges, and enhances paint adhesion. Advancements in ActOn’s shot blasting technology have greatly improved its efficiency and effectiveness, especially when using a shot blasting machine.

Why Use ActOn Shot Blasting Machine for Forgings and Castings?

1. Containment and Safety: our shot blasting machines provide a contained environment, significantly reducing the risk of inhaling abrasive particles and dust, and minimising environmental contamination.

2. Enhanced Efficiency and Consistency: the controlled environment of ActOn sand blasting cabinet ensures precise direction of abrasive material, leading to consistent surface finishes and higher productivity.

3. Versatility in Abrasive Media: these machines can accommodate various abrasive media, including glass beads, steel shots, and aluminum oxide, allowing for tailored finishes from heavy-duty cleaning to smooth polishing.

4. Reduced Material Waste: the enclosed design allows abrasive media to be collected and recycled multiple times, reducing waste and operational costs.

5. Improved Surface Preparation: shot blasting effectively removes rust, scale, and other contaminants, ensuring a clean surface that enhances paint adhesion and coating durability.

Finishing Processes Achievable with Shot Blasting

1. Cleaning: removes rust, scale, and old paint, ensuring final products are free from performance-affecting impurities.

2. Deburring: smoothens burrs and rough edges after forging or casting, providing precise dimensional tolerances.

3. Surface Preparation for Coating: creates a rough texture that enhances paint and coating adhesion, ensuring longevity.

4. Polishing: achieves a smooth, shiny finish for decorative parts using fine abrasive media like glass beads.

5. Peening: improves mechanical properties by introducing residual compressive stresses, enhancing fatigue resistance and durability.

- Summary of Benefits

- Containment and safety

- Enhanced efficiency and consistency

- Versatility in abrasive media

- Reduced material waste

- Improved surface preparation

- Wide range of finishing applications

ActOn’s shot blasting cabinets offer excellent solutions for improving the surface finishing of forgings and castings. For trial opportunities or expert advice, please contact us. We're here to help you explore your options and achieve the best results.

Find out more about ActOn Finishing Ltd on their member profile page here

Member-created content 1 year ago | From members