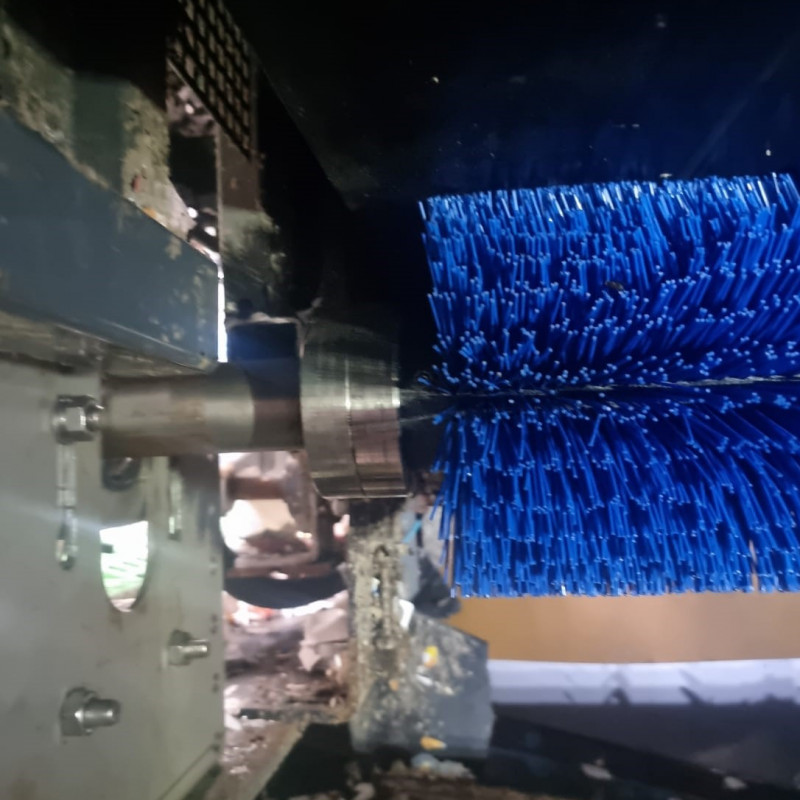

Motorised Brush Conveyor Belt Cleaner

Manufactured by Hoverdale UK Ltd

Product Buying Options

Minimum Order Quantity: 1

Product Description

Motorised Brush Cleaner

Our motorised brush system was initially designed to clean chevron and cleated belts that conventional contact belt scrapers could not clean effectively. However, it soon became apparent that the system was also very effective on all belt construction. Through many years active in the field, we have proven data that shows a reduction in belt stoppages, increasing uptime, and allowing more materials to be processed through the plant.

What is it used for?

Our Motorised Brush Cleaners are highly effective in solving the following problems when processing bulk materials:

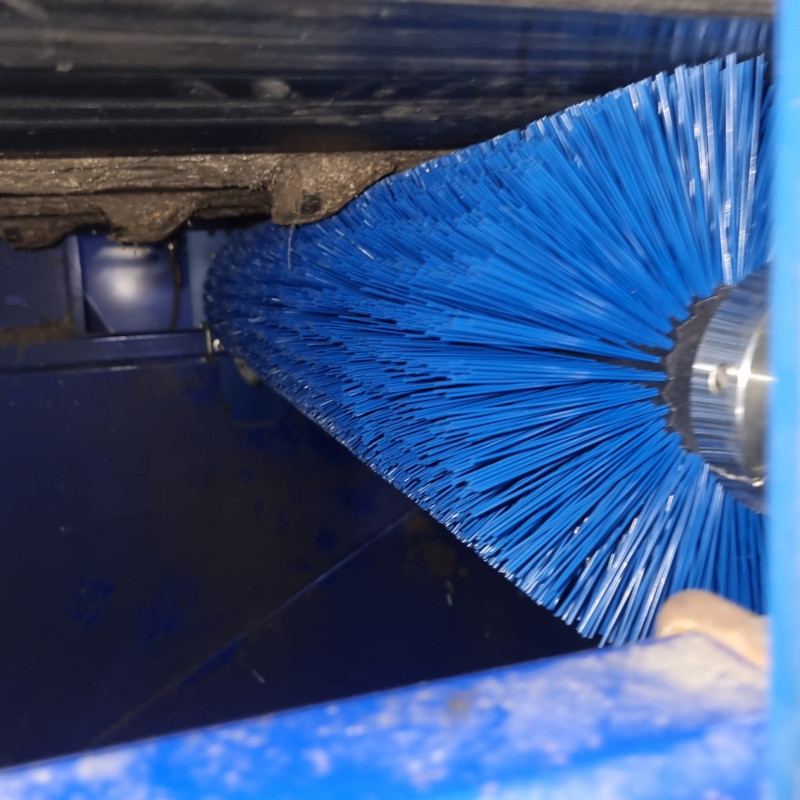

Material stuck to return belt

Material build up on return rollers

Drive drum motors being overloaded

Material under conveyors needing to be dug out regularly

Material build up at tail drum

Excessive or premature belt wear

Material spillage causing hazards

Material becoming airborne causing health safety risks

Belly pans full of material creating a fire hazard

Dirty belts causing optical sorting machine issues

Belt stoppages and downtime.

What industries is it used in?

Our Motorised Brush Cleaners have a proven track record in the following industries:

Sand

Aggregates

Waste

Energy Recovery Facility

Material Recovery Facility

Wood Processing & Recycling

Waste Water Treatment

Cement

Asphalt

Food & Beverage (FDA Approved)

Animal Waste

Plastic Recycling

Incinerator Bottom Ash (IBA)

Aerobic Digestion Plants (AD)

Optical Sorters

Gypsum

Power Generation

Port & Ship Loading

Sea Aggregates

Fertilizers

Gold Mining

Coal

Brick Manufacturing

Glass Recycling

MDF

Construction & Demolition (C&D).

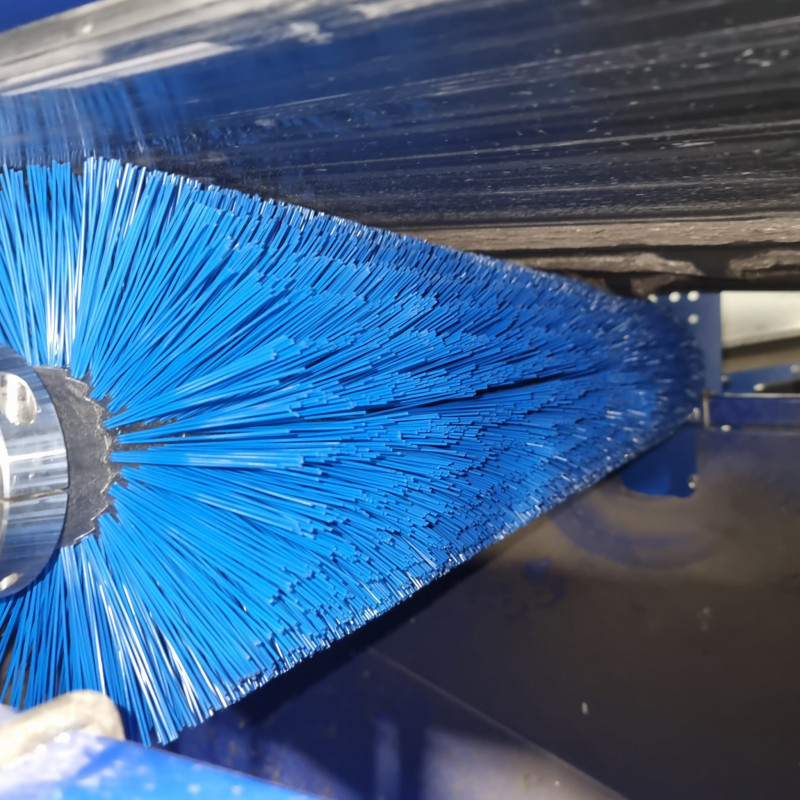

Key Features & Benefits

Suitable for the following belt constructions:

Stainless steel construction for corrosion prevention and longevity

Auto adjusting options as brush wears contact to the belt is automatically positioned to maintain effective contact

Quick release brush cartridge system for easy change and maintenance

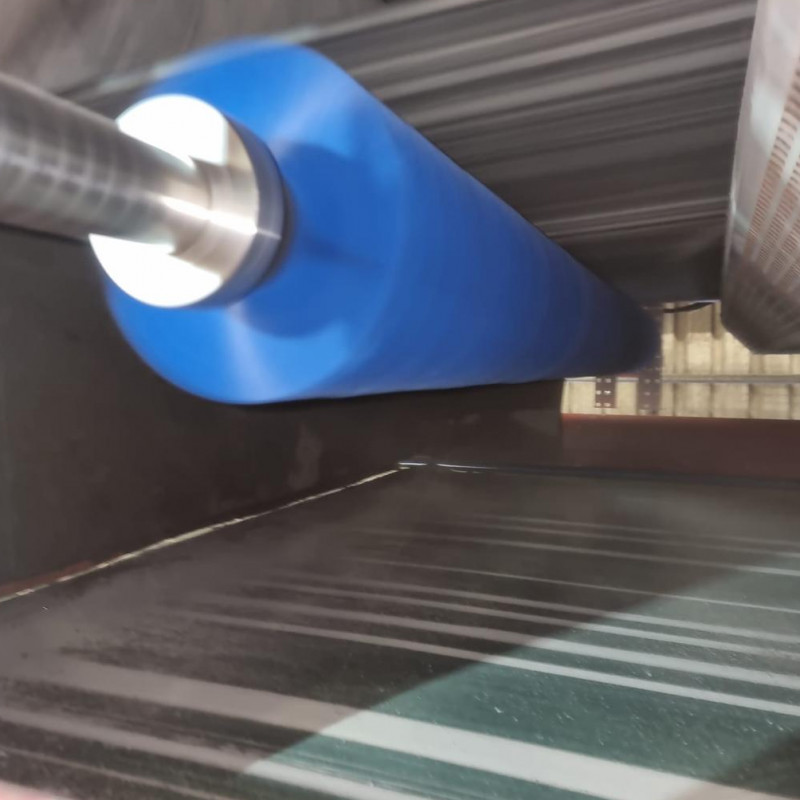

Belt widths from 400mm to 3000mm widths

Brush diameters range from 200mm to 600mm

Semi or fully automated brush disengagement from the conveyor belt

Increase uptime, increase the life of the belt, return rollers, and support equipment

Reduce cleaning resource requirement

Maintain stable production.

Rubber, PVC, Polyurethane, metal slatted, mesh

Hot and cold vulcanised

Mechanically clipped or fastened

Chevron, cleated, flighted, bucket, and flat belt construction.