PCB Assembly Services

Manufactured by Contract Production Ltd

Product Buying Options

Product Description

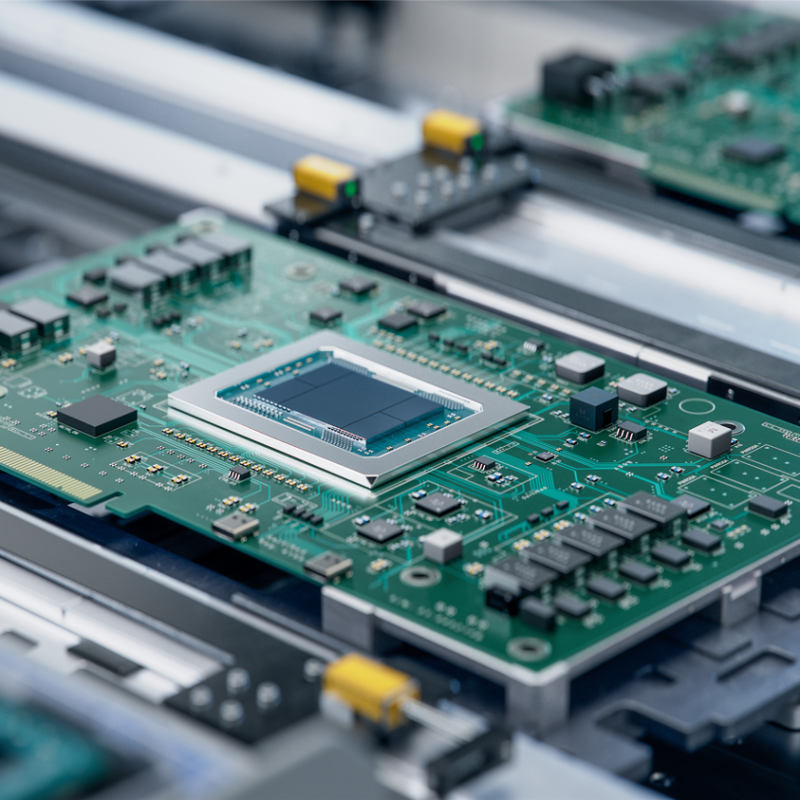

Bringing your electronics projects to life with state-of-the-art PCB assembly.

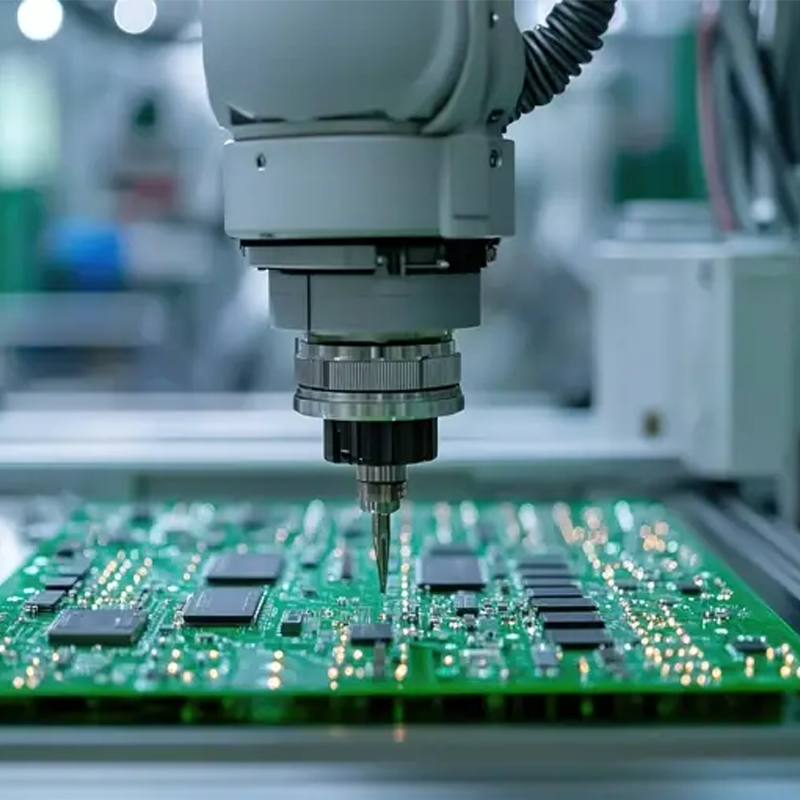

At Contract Production, we have years of experience in the manufacture of complex electronic assemblies and products, working to the strictest standards. Our Panasonic AM100 SMT placement equipment is capable of placing the most challenging components, including fine pitch high pin count BGAs, micro BGAs and 0201 component footprints with repeatable precision and accuracy.

There are two main methods of PCB assembly, both of which we offer here at Contract Production:

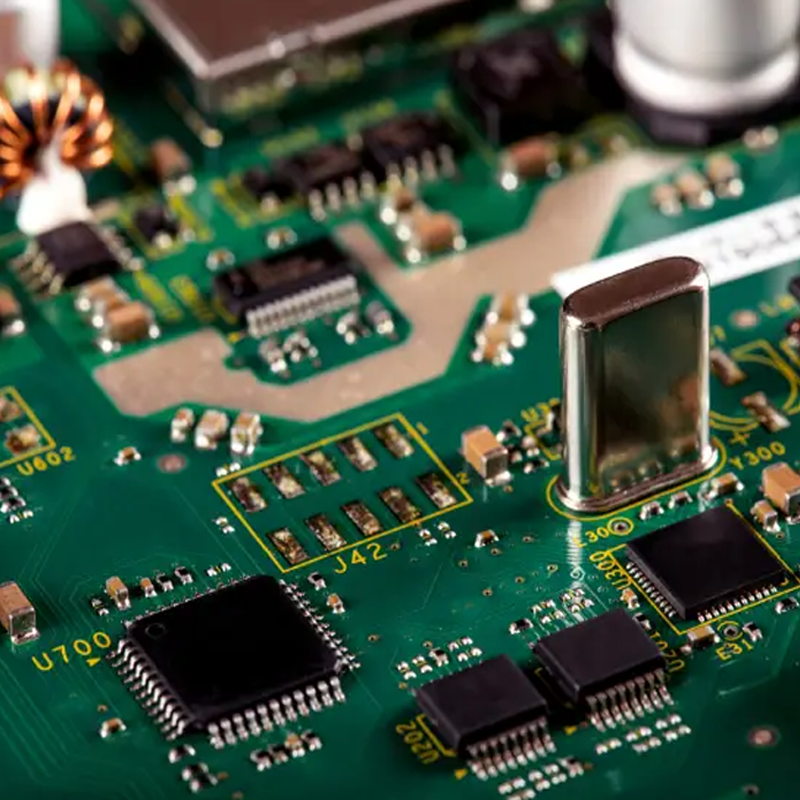

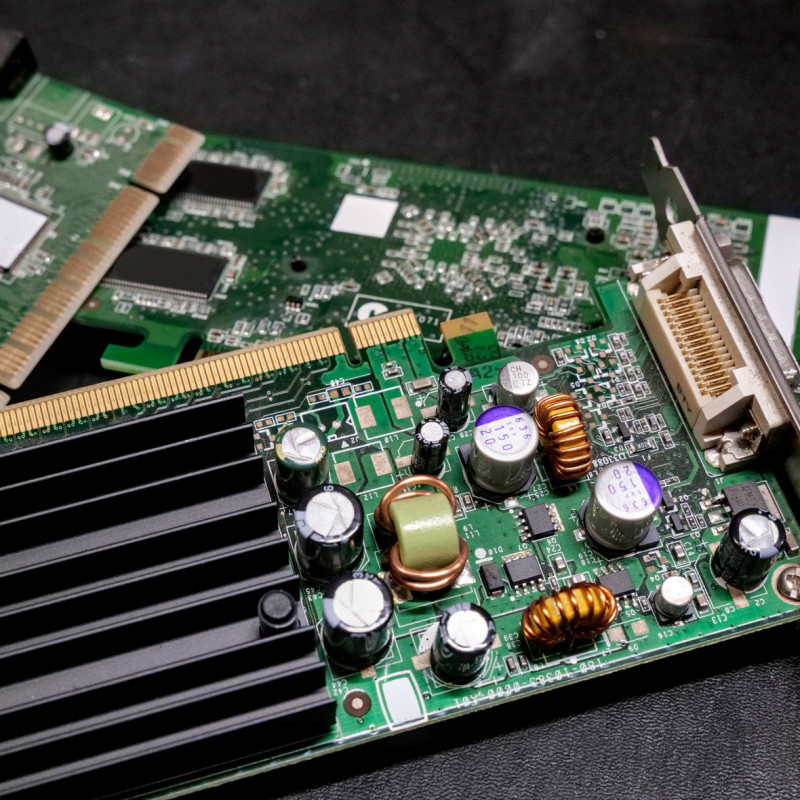

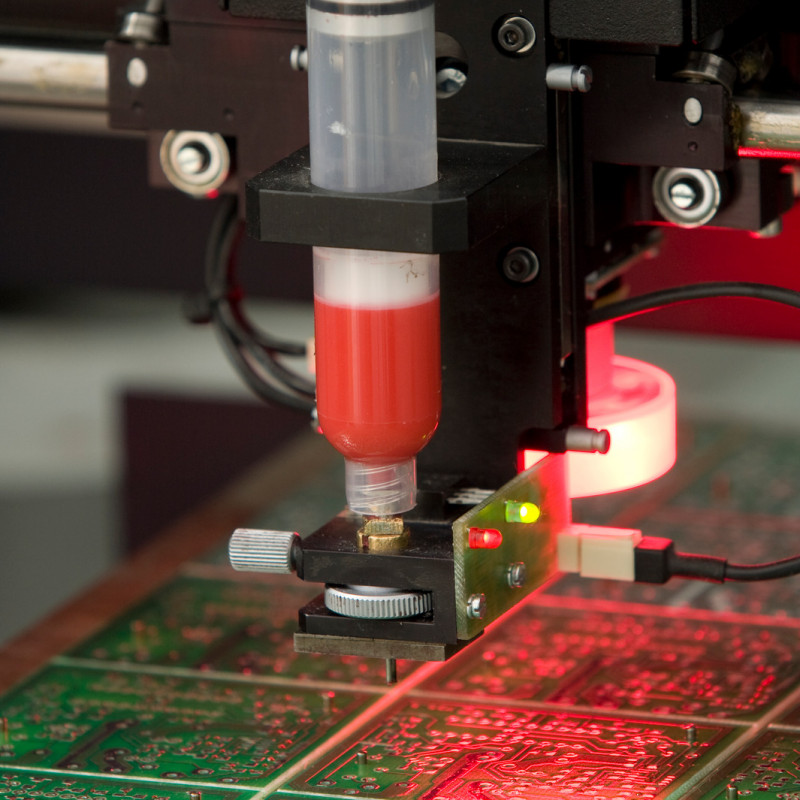

- Surface-mount technology (SMT) where PCB components are fixed to the surface of the board using solder paste. With SMT, the components used tend to be a lot smaller, potentially allowing for the size of your board to decrease.

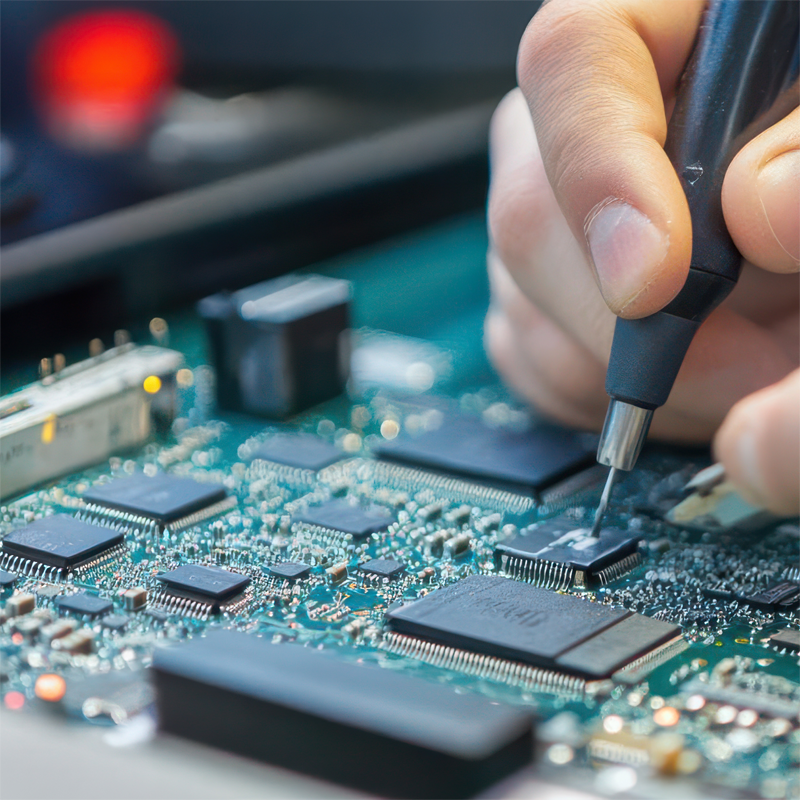

- Through-hole assembly which involves placing components by hand and feeding metal wires through holes on the board, where the reverse side has solder applied to it to keep it in place.

Quality assured in every job

We're committed to providing high-quality electronic assemblies and products. We are an ISO 9001: 2015-accredited company and in addition to this certification, all our electronic assemblies are manufactured, inspected and released to the lastest revision IPC-A-610 standard.

Our PCB assembly solution at a glance

- Automated SMT pick ad place

- 0201 and µBGA footprints

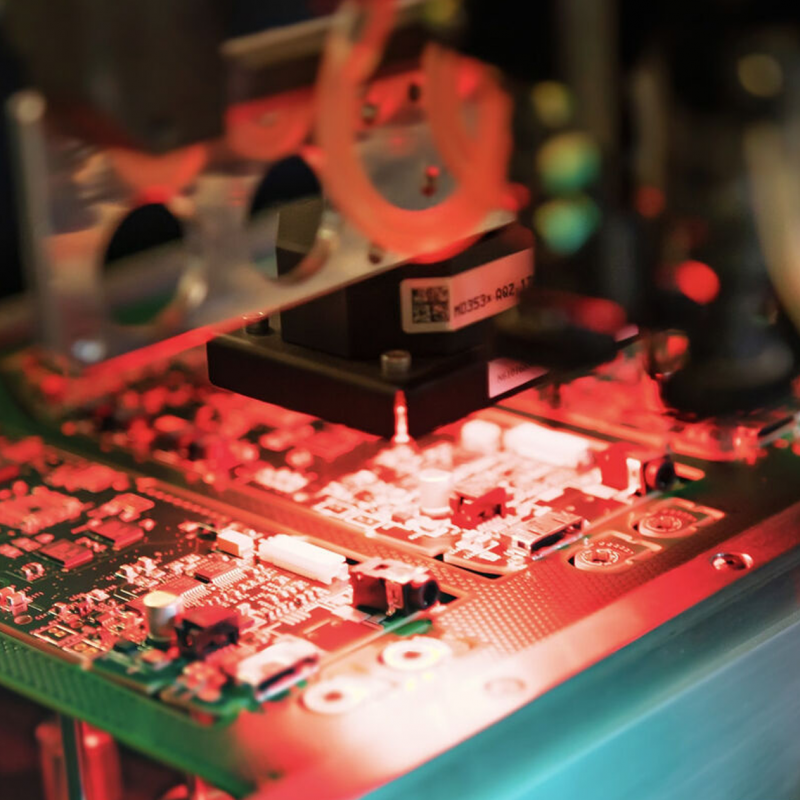

- BGA inspection and verification

- Post-flow AOI (automated optical inspection)

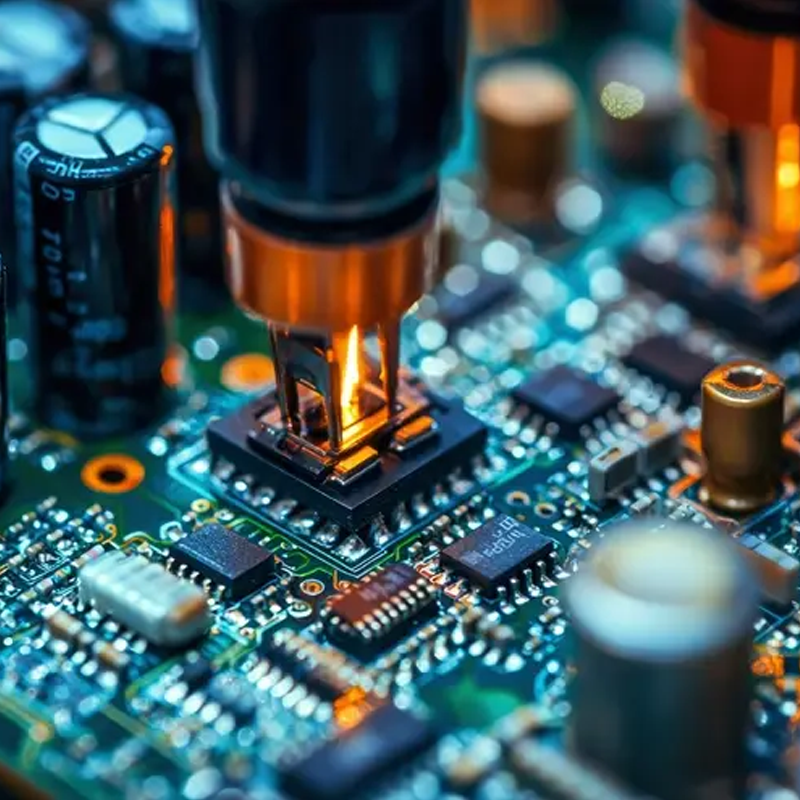

- 8-zone force air convection reflow oven

- Manual through-hole assembly

- Lead-free wave soldering

- SMT rework and repair

- Ultrasonic cleaning

- Full box build assembly

- Fully-tailored test and programming services

Find out more and speak to a member of our experienced team today.