We are happy to announce that ActOn team will be present at the Southern Manufacturing & Electronics Show between the 8th and 10th of February 2022, which will take plat at Farnborough International Exhibition and Conference Centre.

Southern Manufacturing & Electronics Show is a must-attend event for anyone involved in design, engineering production and procurement. It is the place to see all the latest in production hardware, components, consumables and technology; serving a wide range of industries including Aerospace, Defence, Automotive, Electronics, Industrial Machinery, Packaging/ Handling/ Logistics, Energy, Marine, Medical, Mechanical Engineering and Metal Processing. This is a great chance to network and build relationships with the elite of Manufacturing industry. This year our technical representatives will also be available at stand F250 to discuss any of your mass finishing requirements.

5 Reasons to visit us at Southern Manufacturing & Electronics Show

- You can be the first to find out about our new Wet Blasting Technology range. NP Wet Blasting cabinets are perfect for applications such as cleaning, descaling, deburring, roughening, oil or grease removal, die cleaning as dimensions are not affected, or to achieve a smoother surface in compliance with HACCP. These machines can be used with all kinds of inert abrasives.

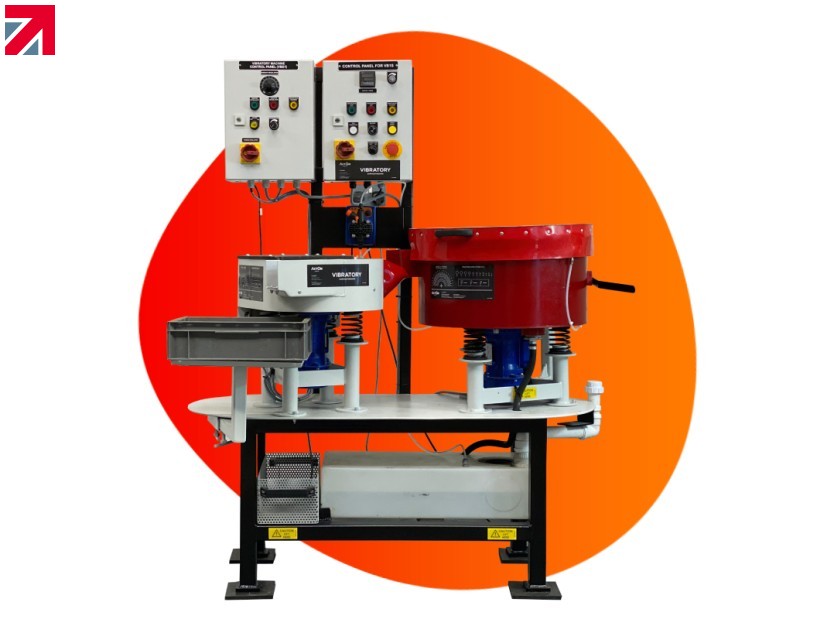

- Learn about the latest Mass Finishing Technology available and how it can be applied on your components. You will be able to check at our stand, F250, the SPU-1 system. This Single Portable Unit is ideally suited for small batch works and delicate components. SPU-1 is perfect for deburring, descaling, degreasing, cleaning, smoothing, radiusing, polishing and drying. This is both an excellent and economical finishing option.

- Discover our Centrifugal High Energy machines, more than 15 to 20 times faster than traditional Vibratory Finishing machines.

- Already have a finishing machine? Then we recommend checking our range of finishing consumables. From ceramic media, plastic media, shot blasting & peening media, agro and pre-treated media, burnishing media to liquid compounds & abrasive powders & pastes, these consumables will offer you superior processing results.

- If you need a Mass Finishing solution and do not have the experience, the capacity required or are not ready to invest in Mass Finishing equipment, ActOn can offer specialist services. Our team will be available to discuss with you about the best Finishing Subcontract Solutions for your requirements. If you decide to access our subcontract services your benefits will include:

- Quick turnaround time based on the delivery time of components from customer.

- Controlled subcontract processes to ensure constant high quality finishing on all components.

- Transport option available to facilitate a quick turnaround time.

- Free Trial and technical consultation to ensure finishing result is as per customer’s requirement.

… still not convinced? Here are a few more reasons why you should join us:

We pride ourselves of being the UK’s leading expert in the design and development of surface finishing machinery, consumables and subcontract surface finishing solutions. At ActOn Finishing we offer solutions for vibratory finishing, high energy finishing, shot blasting and wheel blasting, electropolishing & waste water treatment. All the equipment is suitable for a range of applications such as deburring, descaling, polishing, cleaning, mirror finishing, radiusing, smoothing, drying and much more.

“We are the only manufacturers in the UK of this type of equipment and we very much focus on process development, which is tailored to our customer needs. Moreover, all materials and machinery are subjected to extensive testing at our laboratory, ensuring the efficiency of our process is continually improving.”, says Sid Gulati, Managing Director at ActOn.

Register for your FREE Tickets now and don’t miss out on the opportunity to support the British manufacturing sector!

Find out more about ActOn Finishing Ltd on their member profile page here

Member-created content 3 years ago | From members