Many manufacturing projects benefit from the use of surface finishing. Surface finishing for medical implants, in particular, is critical to the manufacturing process since it determines how a part's surfaces are prepared for usage.

Surface finishing has always been viewed as a process by-product rather than a design feature in metal additive manufacturing, particularly in the healthcare sector.

This article will delve into the importance of surface finishing for medical implants and instruments to create an understanding of the finishing requirements within the medical industry.

Why is surface finishing for medical implants important?

There are many crucial factors that play a role in the process of surface finishing for medical implants to ensure a successful process.

Surface finishing essentially increases resistance to corrosion and ensures parts perform at the level required by the medical industry which is of utmost importance.

A wide range of materials can be processed, from high-strength metal alloys, polymers, and 3D printed components to forged and casted parts.

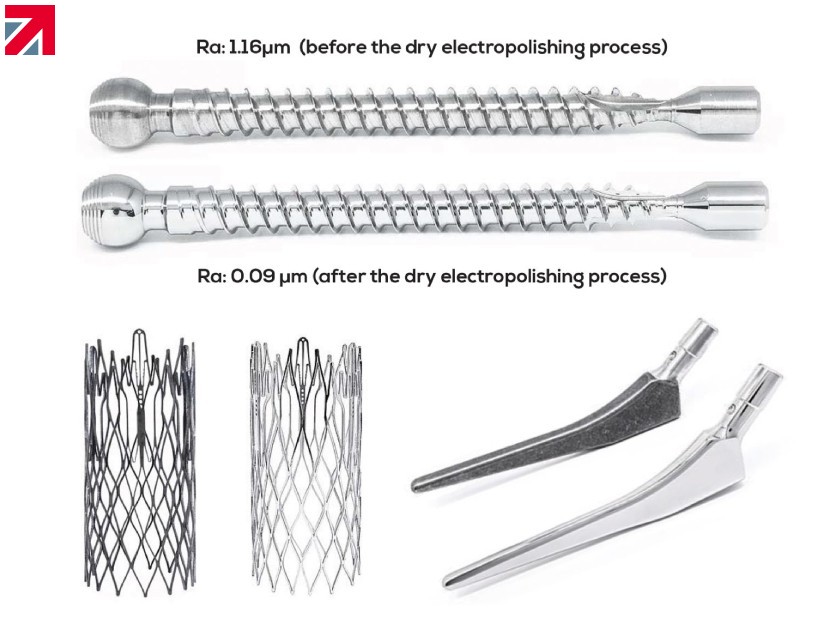

It’s important to have a clinically proven finishing process that complies with the safety regulations imposed by this industry. Through surface finishing techniques, you can achieve a deburred, smooth, and mirror polished finish that benefits manufacturing by reducing processing times and produces a repeatable, quality product.

The benefits of using surface finishing techniques

There are several benefits to using specific surface finishing techniques to produce efficient medical implants and instruments.

Manual finishing processes are known to be labour intensive, with the disadvantages of rework, high rejection rates and inconsistent results. Mass finishing, however, allows you to process high volumes, reducing processing times and offering repeatable and consistent results, every time.

This technique of surface finishing medical implants ensures that the component’s geometry is integral, therefore, saving you time and lowering your production costs as a result.

Industry standards for medical implants and instruments

The healthcare industry has stringent standards when it comes to manufacturing medical implants. These requirements can make a difference in the success of a surgery and the welfare of a patient.

Some of these standards include:

Biocompatible processes – The healthcare industry requires clinically proven processes and products which guarantee their compliance with the most demanding safety regulations. To ensure low risk of bacteria contamination, a smooth finish is most effective.

Corrosion resistance – The lifespan of an implant or instrument can be influenced by corrosion. Through mass finishing techniques, parts can be protected from corrosion by; using compounds in the wet process which include corrosion inhibitors and by drying the parts in ActOn’s dryer and agro-media. It’s important to know that all of our agro media comes in a treated, bovine-free form and is well accepted by the industry.

Cosmetic appearance and functionality – Reducing the parts roughness, achieving a smooth finish and a mirror polished finish are mandatory in the healthcare industry. A surgeon can’t operate with a scalpel which has burrs, and a patient will most likely suffer health issues if a femur implant is not polished to industry standards.

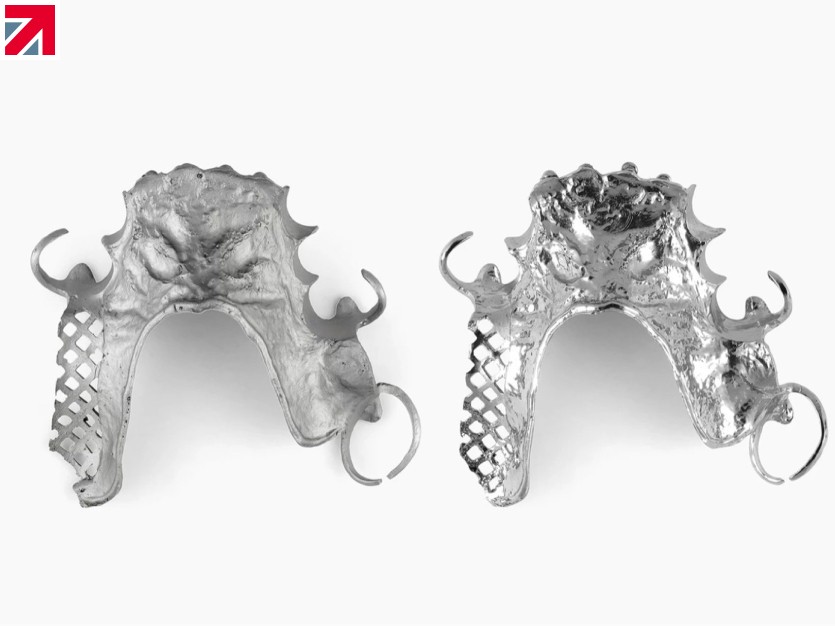

The functionality and cosmetic appearance of these components can be achieved in an efficient manner via mass finishing. For example: While the CHEF series is perfect for removing machining lines and polishing titanium bone plates, femur, and tibia implants, stainless steel eye clips can be deburred in a vibratory finishing trough and dental partials can be mirror finished in the DLyte machine.

For a successful surface finishing for medical implants, we recommend that you determine the correct machine, media, and compound. At ActOn we have worked with highly skilled manufacturers and our engineers have understood the numerous challenges faced in the industry to develop suitable processes.

What materials and components can be surface finished?

Often medical instruments and implants are made out of high-strength metal alloys such as titanium, stainless steel, cobalt chrome and tungsten carbide. The main reason for this being that these components must be durable in an environment where they are exposed to corrosion such as constant cleaning of instruments. They need to have resistance against scratching and pitting, with the ability to perform for a long period of time. Nonetheless, there are medical instruments and implants such as dental implants, which are manufactured out of lower-grade metals and polymers.

Our High Energy machines are perfect for a range of surface finishing for medical implants and instruments as all of the above materials can be processed via these finishing techniques. These can be aggressive enough to handle your toughest burr, yet precise enough to process the most delicate piece without the need for any fixturing.

The DLyte series is designed to surface finish fragile medical components like needles and stents, as it has a controllable process and works better at a micro and macroscopic level.

For additive manufactured polymer parts, the AM Blasting series is perfect for removing the residue after the 3D printing process, even from parts with complex geometries. To achieve a smooth finish, vibratory finishing is perhaps the most commonly used mass finishing method. The gentle action in the machine allows for processing fragile parts, whilst still being able to achieve a good reduction in surface finishing.

We hope this article has given you a deeper understanding of surface finishing for medical implants and the importance of it within the medical industry. If you would like to discover more or have any related queries, then get in touch with our friendly team and we’ll be happy to help.

Find out more about ActOn Finishing Ltd on their member profile page here

Member-created content 3 years ago | From members