HOWDON Torque Limiters has been involved in the design and manufacture of torque limiter couplings for over 40 years and, in recent times, has worked with other engineering companies on developing test rigs for the automotive industry.

Paul Reid, Project Manager at Zytek Automotive Ltd, Continental Engineering Services, explains:

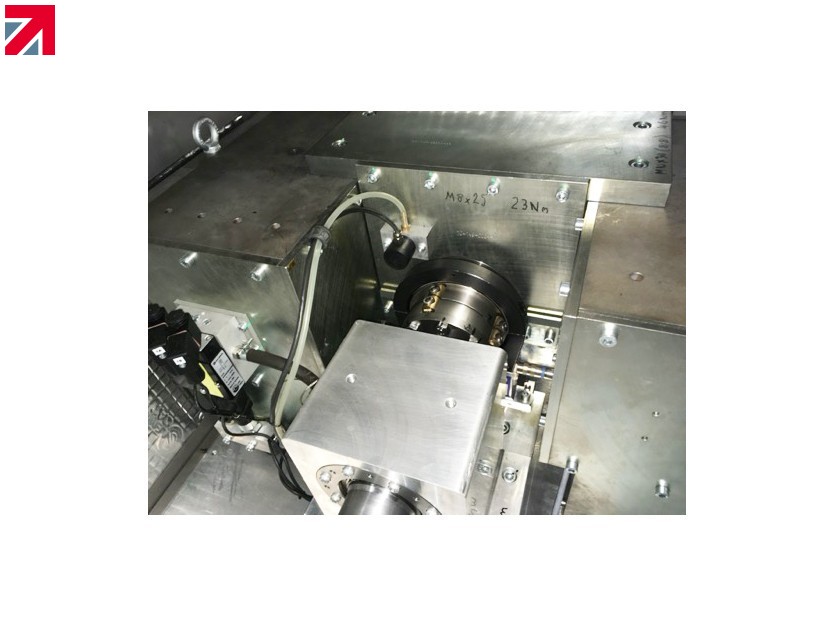

"We had been developing a test rig for two years to help a client test a manual clutch system for new Hybrid and Electric vehicles. The problem was that we needed a torque limiter coupling that could run up to speeds of 6500 rpm and 900 Nm, but be small enough to fit into our newly designed test rig.

Howdon Wedgegard torque limiters gave us the following advantages over standard slip clutches:

First and foremost, Safety

Torque limiting couplings play a large role in test rig safety as they protect the shafts from breakages due to lock-up conditions. If a rig were to lock without them, it would most likely result in a shaft breakage, which would eject significant fragments to cause injury, even when guarded. Fitting the Howdon WedgeGard coupling significantly reduced the effort to design the guards and test them, as the ejected fragment size (and energy) is vastly reduced.

Direct mating to an HBM-T40B torque flange for protection of expensive sensors

The limiter coupling also had to mate directly to an HBM T40B torque flange, an expensive torque sensor widely used in the automotive industry. The torque flange usually has a 100 per cent overload around 1000 Nm so the WedgeGard must break before 2000 Nm.

Reliability – no moving parts

Having looked around in the market, Howdon seemed to have the expertise to create a bespoke torque limiter that would work for our application. Unlike other solutions we’d tried and products we’ve used in the past, Howdon’s DIN 120 coupling didn’t need any balancing and worked the first time.

Relatively easy to achieve alignment of 30 microns

We could achieve <30 microns with just a screwdriver forced in the gap between the two flanges, then lock the bolts on the wedgepins to hold the alignment. There was significant lash in the bearings without the wedgepins at well over 30 microns which could cause a vibration.

Promotes inspection in the testing process

When a pin breaks a technician must fit a new one. This automatically promotes an inspection, as the guy needs to have hands-on the rig, whereas a slipper clutch will recover and nobody will ever look at why it slipped. So if the rig bearings were deteriorating and causing excessive torque (friction, etc), this would be found by changing the pins.

This was a quick turnaround job and their customer service was excellent, answering all our technical queries straight away."

Howard Miles, MD of Howdon: “Our products have always been designed to the highest standard and we guarantee that the limiters will disengage at the required breaking load within 3% of accuracy. Unlike slip and ball clutches which can degrade over time, our mechanical solution continues to break at the same point for year after year, meaning a guaranteed level manufacturing success and quality control in-car part production. Our torque limiters have also found their way into full testbeds of whole vehicles as well, allowing manufactures to test everything from motors and braking systems to clutches.”

Chris Isaac, Marketing Manager at Howdon, added: “It’s great to collaborate with other engineering businesses in the UK to help support EV manufacturing around the world. We’re proud to be part of the automotive industry and Made In Britain.”

Find out more about HOWDON Torque Limiters & Industrial Brakes on their member profile page here

Member-created content 5 years ago | By Made in Britain