DLR Elastomer Engineering have been manufacturing rubber products for over 125 years. Supplying seals, gaskets, o-rings, bladders, diaphragms, vibration mounts, suspension bushes and much across all industrial sectors.

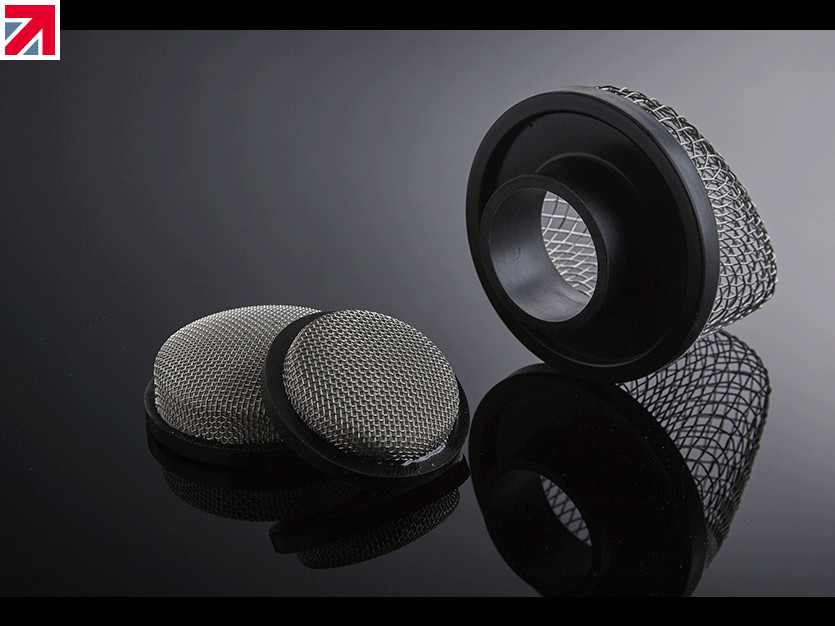

However, we are also experts in the area of bonding rubber to metal (or metal to rubber). This is a very specific capability that requires meticulous preparation and attention to detail to ensure an effective and lasting bond between the rubber and metal components.

The process goes by several names including:

- rubber-to-metal-bonding

- metal-to-rubber-bonding

- co-moulding

- over moulding

Regardless of name, attention to detail along with a tried and tested method are required to ensure the finished product is fit for purpose and safe in use.

All metal surfaces must undergo a multi-stage preparation to remove any inherent grease or contaminants.

The surfaces must also prepared with an appropriate mechanical roughening to provide a key for the rubber to bond to.

The correct rubber grade must also be selected to give the strongest and most reliable bond.

Tooling must be designed to support the metalwork and ensure correct alignment.

In short, it's a complex process and all stages must be carried out correctly to avoid failure.

Typical applications include:

- Suspension arm assemblies

- Machine feet

- Filters seals

- Accumulator bladders

- Bonded pump diaphragms

- Anti-vibration mounts

Along with the metal and rubber bonding capability, we are also well versed in the bonding of other substrates. These include plastics, textiles and even PTFE (AKA Teflon - the most non-stick product known to man).

Find out more about DLR Elastomer Engineering Limited on their member profile page here

Member-created content 1 year ago | From members