Imperative to the gear manufacturing process is controlled quality assurance. Ensuring any gear produced is within tolerance and to specification is of utmost importance, underlying the whole production process. Assisting with these efforts is the crucial analysis and inspection equipment which ensure that gears conform to these requirements.

One such piece of equipment is the not so small, but very mighty; Leitz Reference HP 5.4.3. supplied by Hexagon. A world-class co-ordinate measuring machine that’s also a tremendously capable gear inspection centre. The perfect partner for our gear inspection needs!

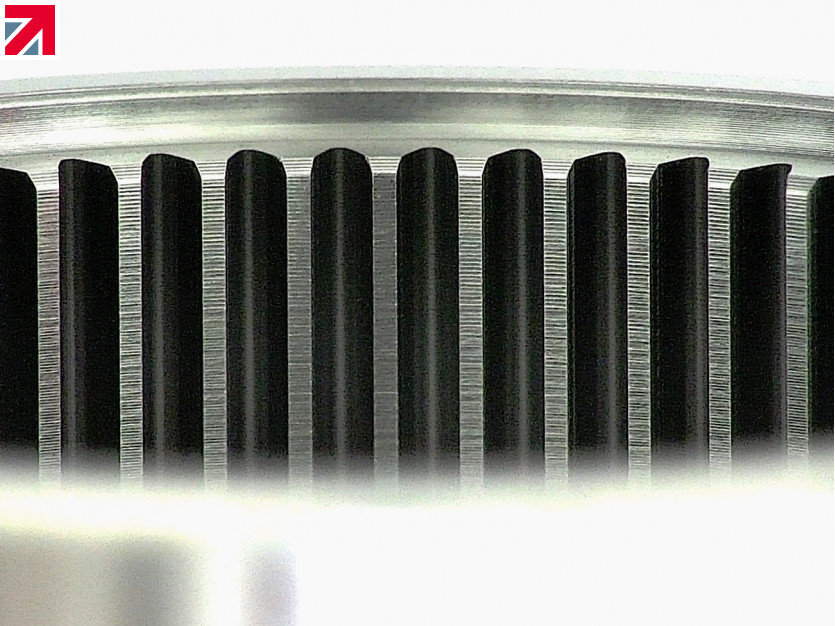

The powerful Leitz HP S X3 analogue scanning probe and unmatched Quindos Gear software are capable of measuring spur gears up to Ø350mm and bevel gears up to Ø200mm with sub-micron accuracy.

Capable of inspection on any component up to 500 x 400 x 300mm in size it offers:

- Leading metrology software Hexagon Quindos for precise gear measurement

- Volumetric Length Measuring Error of 0.7 + L/400 µm

- Maximum permitted table load of 250kg

Hexagon’s Quindos makes our gear measurement fast and efficient. The advanced algorithms in QUINDOS are certified for a wide range of international standards such as DIN, ISO, JIS, AGMA, ANSI, CNOMO and meets many individual industrial standards.

We are continuing our deep dive into power skiving next week, where we will be looking into the types of gear we manufacture and what applications they have within industry.

Please do keep up to date by subscribing to our newsletter and follow our LinkedIn.

Find out more about R E Thompson on their member profile page here

Member-created content 3 years ago | From members