An MRP system is a system used by manufacturers to manage their business, from receipt of a customer order through to raising an invoice.

What does MRP stand for?

MRP has two definitions, depending on whether it is MRP1 or MRP2. In the case of MRP1, it stands for Materials Requirements Planning and for MRP2 it means Manufacturing Resource Planning.

What is MRP1?

MRP1, which was developed during the 1960s, helps manufacturing businesses to manage their materials, by aggregating demands and placing orders in a timely fashion. Aggregating demands helps to reduce the unit cost of materials and the delivery costs associated with them. Placing orders in a timely manner ensures that materials are ordered in time, but also not too early. In this way MRP1 helps to reduce costs and improve cashflow.

Material lead-times, minimum order quantities (MOQs) and material availability are the key constraints managed by MRP1. MRP1 assumes there are no resource constraints, when planning the acquisition of materials.

What is MRP2?

MRP2, which was developed in the 1980s and beyond, helps manufacturing businesses to manage their materials and their resources (e.g. labour, machinery, processes). MRP2 effectively builds on MRP1, by adding the functionality of managing resources.

In addition to the benefits of MRP1, MRP2 helps to manage resources so as to reduce waiting times, increase efficiency and improve customer on-time delivery.

The key constraints managed by MRP2 are those of MRP1 plus resource capacity and resource failure, which can be both internal and external.

What is the most common form of MRP used today?

Given that MRP2 builds on MRP1, most systems today are MRP2 based. This article will therefore refer to MRP2 when discussing the functionality, merits and issues associated with MRP.

What is the difference between MRP and ERP?

MRP and ERP are both planning systems used to manage a company's materials and resources, but there are significant differences.

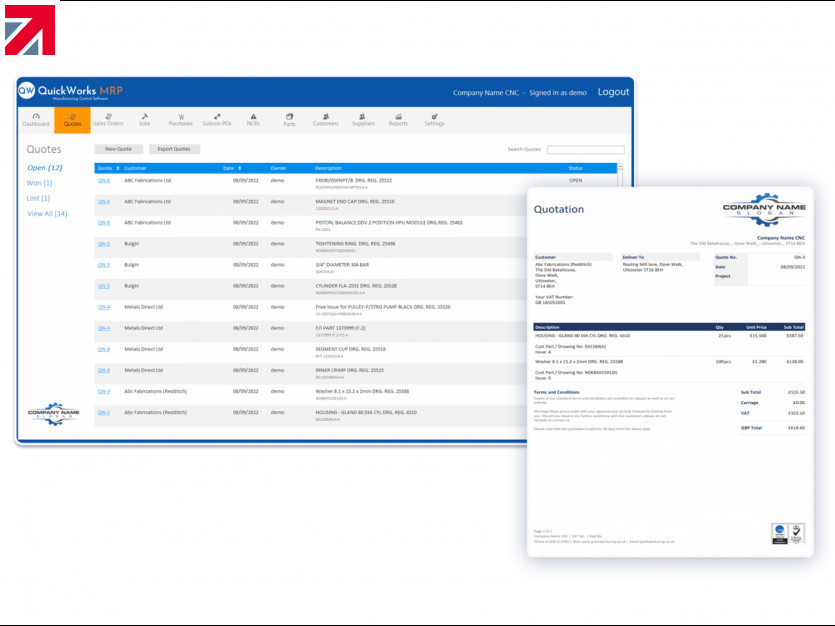

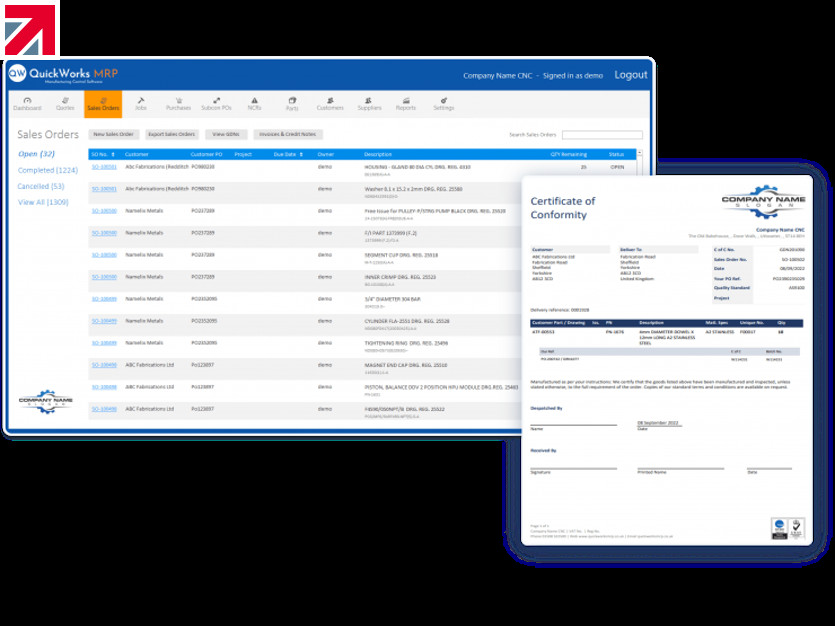

As discussed earlier, MRP (Manufacturing Resource Planning) is primarily focused on the management of materials and resources, typically in a manufacturing business. The business process scope is usually from receipt of customer order through to raising an invoice following the delivery of the product.

ERP (Enterprise Resource Planning), on the other hand, is a much broader system that builds on the foundations of MRP to include greater functionality, typically including, but not limited to, accounts, customer relationship management (CRM) and supply chain management (SCM).

Where MRP is typically deployed in manufacturing businesses, as ERP systems have broader capabilities, they are adopted by companies in most industrial and commercial sectors.

If you would like to know more, why not visit www.quickworksmrp.co.uk or call us on 01455 372 123.

Find out more about QuickWorks MRP on their member profile page here

Member-created content 2 years ago | From members