Plastic Extrusion for Construction and Building Projects

Manufactured by D W Plastics Ltd

Product Buying Options

Minimum Order Quantity: Minimum order quantities (MOQ) vary according to the profile, but usually start at around 3000-5000 metres. As the profiles are made to order we can cut to various lengths and supply in diffe

Product Description

Apart from the obvious products, such as soffits, wall cladding, guttering, pipework, cable sheathing and insulation, plastic extrusions in construction are used in everything from the concrete foundations to the final interior finishing.

Plastic products have a huge role in sustainable construction helping to provide excellent insulation properties and are second to none when it comes to long-term durability and value. They are used both in the traditional and modern methods of construction, whether is it the refurbishment of older properties or in the production of new temporary and permanent modular housing and structures.

The excellent key properties of certain plastics make them ideal for use in the building sector, for example: good UV resistance, good impact strength, good fire retardancy, good electrical insulation and damp proofing properties, and weight saving.

Why not get in touch with us directly to discuss your plastic extrusion requirements whether it is pipes, conduits, frames, ventilation ducts, etc. We can manufacture bespoke, high-quality cost-effective products to suit your needs.

Having an experienced team and all equipment under one roof guarantees you a structured process. We’ll work closely with you to design and produce your bespoke plastic building profiles that are custom-manufactured to meet your specifications.

Our most common requests include:

- Conservatories

- Cladding

- Partitions

- Housings

- Trims

- Roofing

Get in touch

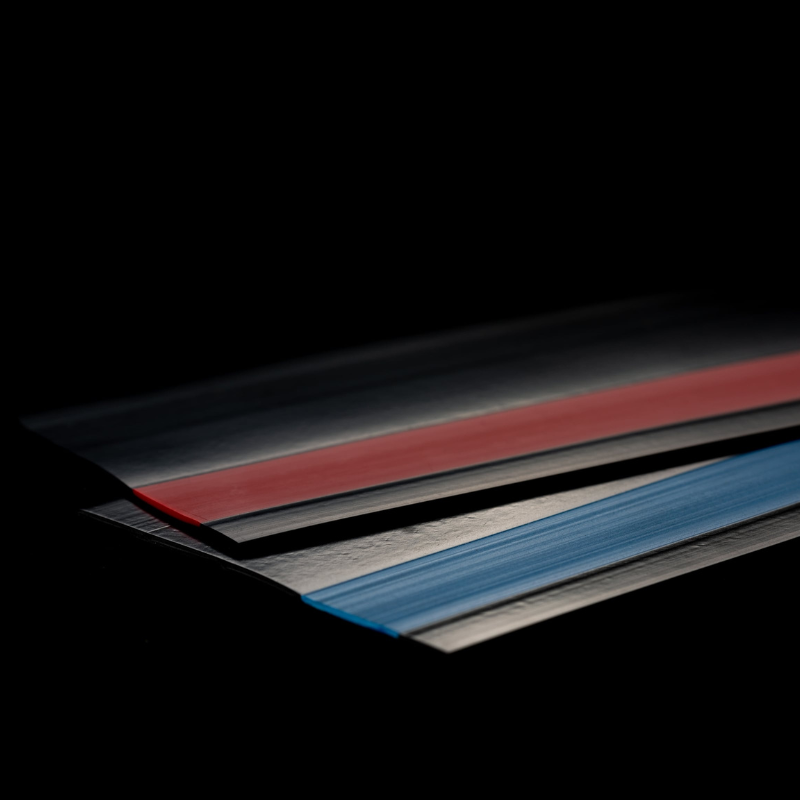

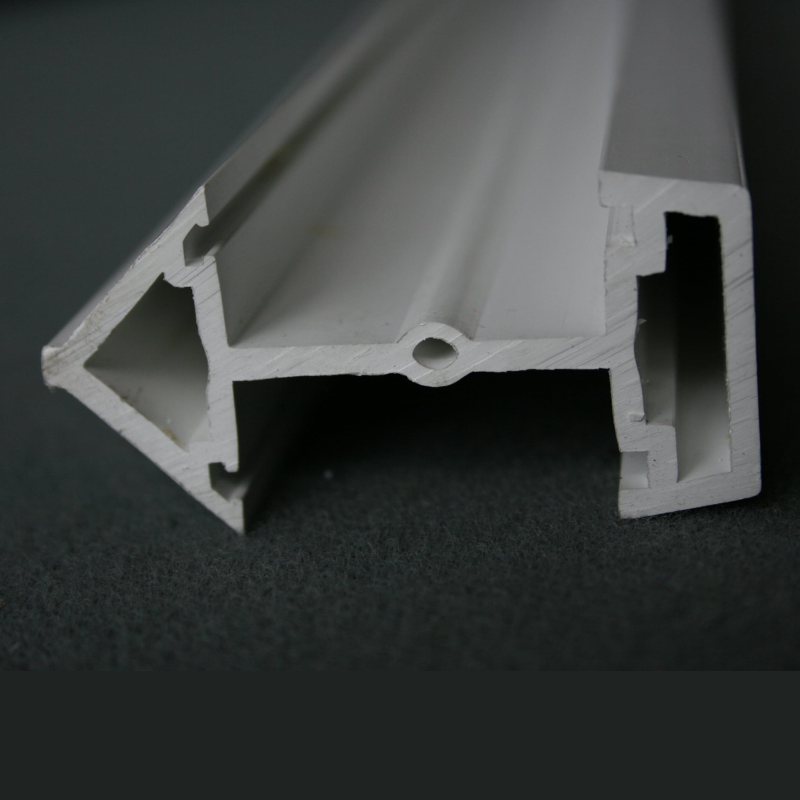

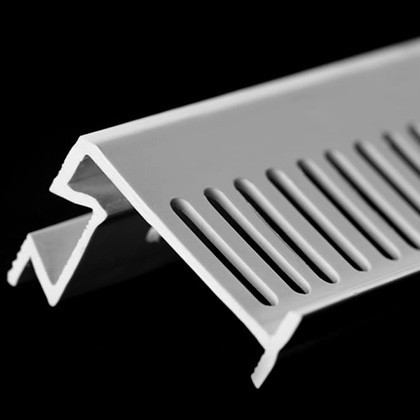

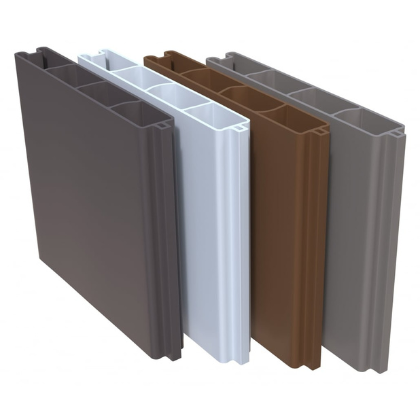

We are experienced in the design and supply of extruded plastic channel profiles. White plastic profiles made from rigid PVC, such as self-adhesive mini-trunking, partition joints and division bars, angle profiles used for beading, corner covers, guards and protectors, capping and edging trims (J and C joints), H and T-sections, U-channels and plastic strapping are available in different sizes. Please see the photos below to view some of the standard extrusion products.

The accurate design, production and maintenance of tooling are vital to an efficient extrusion process and therefore to the quality of our customers’ products. Profile dies are wire eroded to ensure the highest-quality and specifications of the extrusions are achieved. Customer dies are made from high-grade chromium steel to preserve their longevity, and are retained exclusively for repeat orders.

If the PVC profile you require is not listed, we offer a bespoke plastic extrusion design service so please get in touch with us to see if we can help further.