Plastic Extrusions for Safety & Security Products

Manufactured by D W Plastics Ltd

Product Buying Options

Minimum Order Quantity: Minimum order quantities (MOQ) vary according to the profile, but usually start at around 3000-5000 metres. As the profiles are made to order we can cut to various lengths and supply in diffe

Product Description

D W Plastics’ technical team welcomes the opportunity of working closely with customers to develop bespoke plastic extrusion components for safety products to ensure that they comply with hygiene, fire and Health & Safety regulations. Products such as protective edge and corner strips, hygienic cladding profiles, fire blanket holders, and sealing strips, to name but a few, can be extruded to customer specifications.

Get in touch

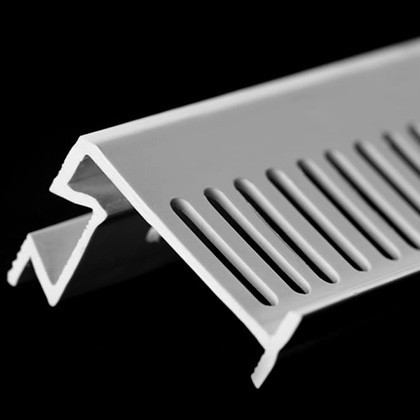

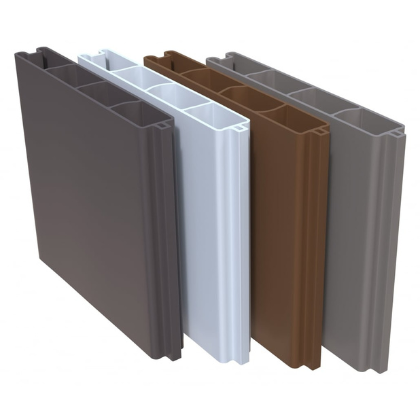

We are experienced in the design and supply of extruded plastic channel profiles. White plastic profiles made from rigid PVC, such as self-adhesive mini-trunking, partition joints and division bars, angle profiles used for beading, corner covers, guards and protectors, capping and edging trims (J and C joints), H and T-sections, U-channels and plastic strapping are available in different sizes. Please see the photos below to view some of the standard extrusion products.

The accurate design, production and maintenance of tooling are vital to an efficient extrusion process and therefore to the quality of our customers’ products. Profile dies are wire eroded to ensure the highest-quality and specifications of the extrusions are achieved. Customer dies are made from high-grade chromium steel to preserve their longevity, and are retained exclusively for repeat orders.

If the PVC profile you require is not listed, we offer a bespoke plastic extrusion design service so please get in touch with us to see if we can help further.