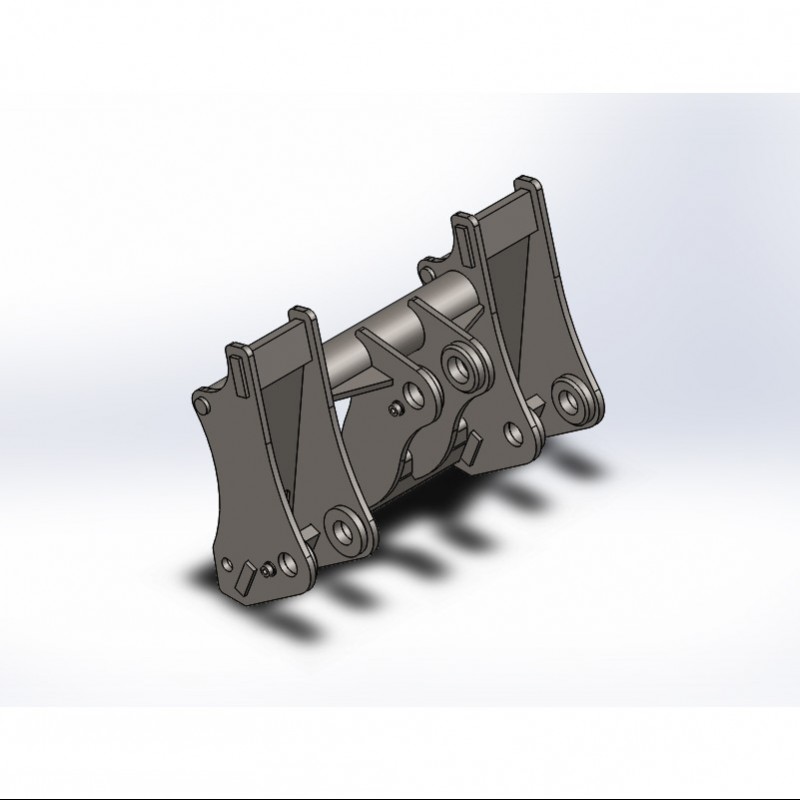

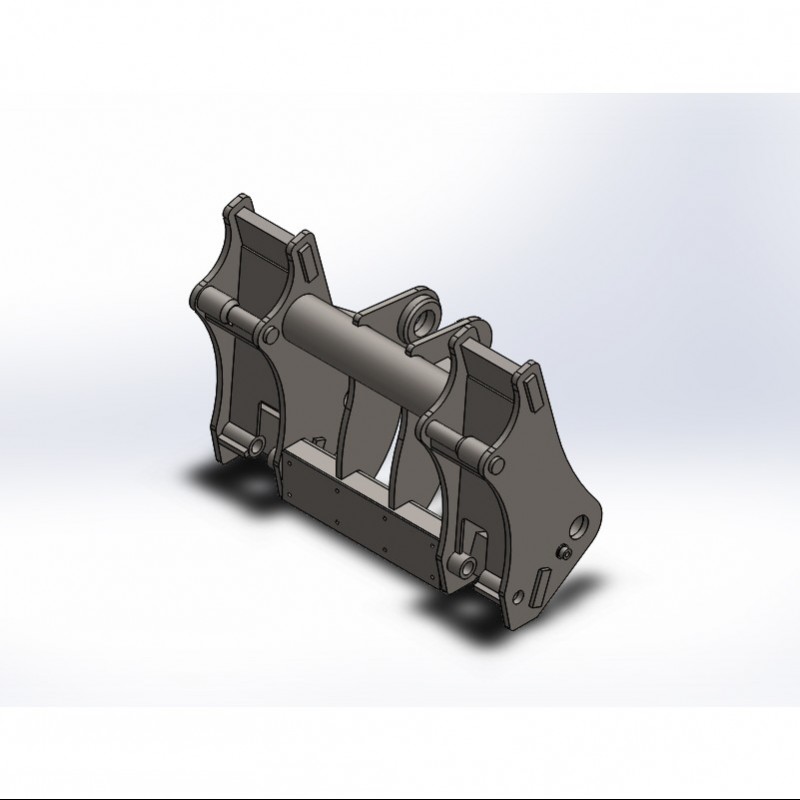

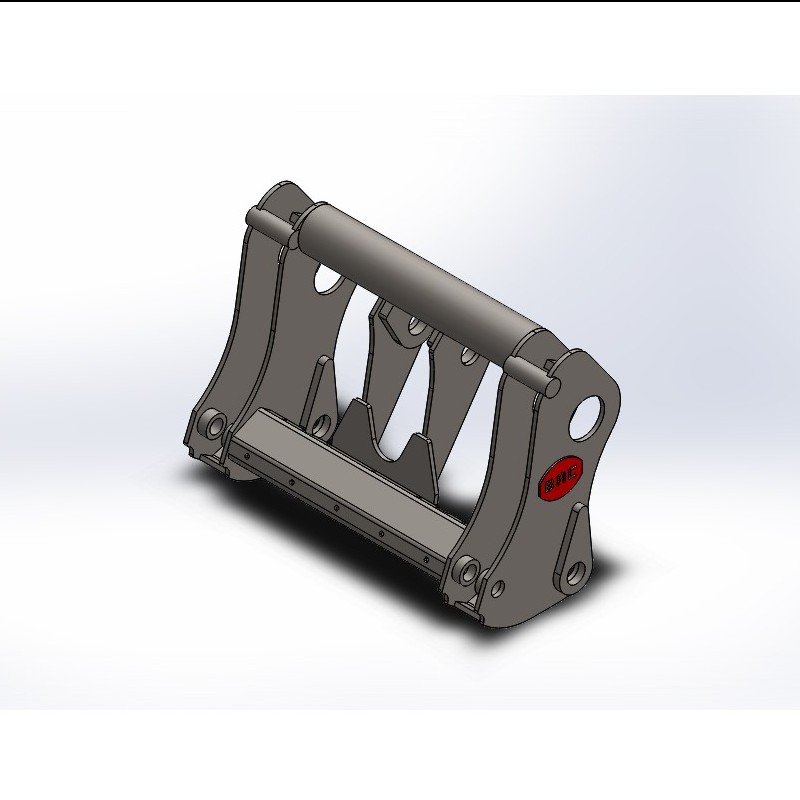

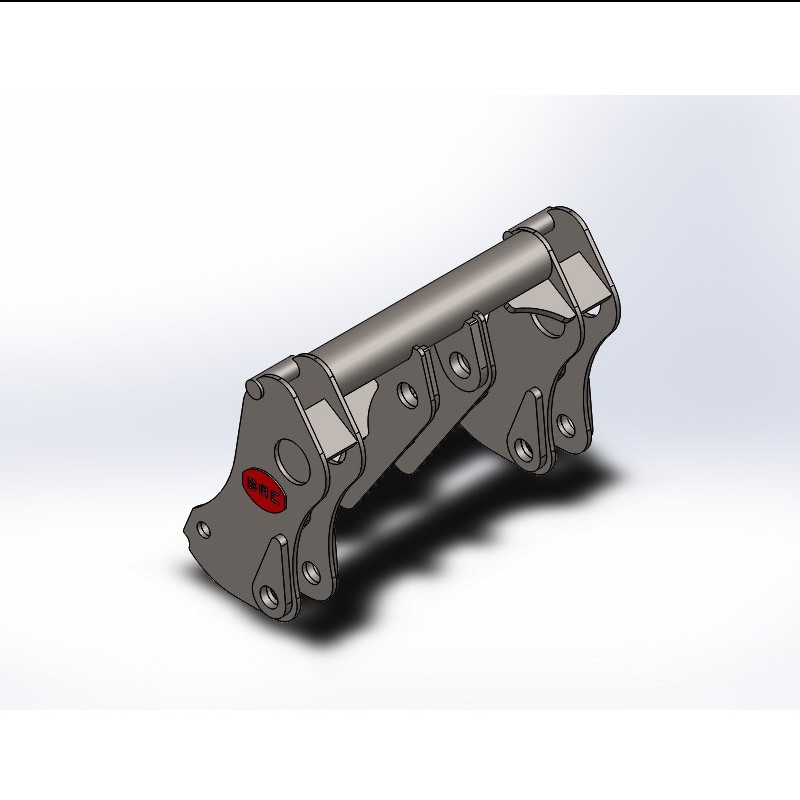

Quick Hitch Brackets

Manufactured by B A Caulkett Limited

Product Buying Options

Product Capacity: 5 per week

Minimum Order Quantity: One

Additional Sales Information: All Quick Hitch Brackets are made to a customers exact specification so that they are perfectly suited to the loading shovel / telehandler being used and the application. Visit our factory and showroom and talk to our design team +44(0) 1440 70642

Product Description

Our Quick Hitch Brackets are manufactured to the highest standards and can be supplied to fit any make or model of loader or materials handler.

Quick hitch (QH) brackets are a latching device that enables attachments to be connected to plant and interchanged quickly. Research from HSE identified that an excavator operator may change the buckets on their excavator up to thirty times a day in order to maximise the machine productivity.

To see our complete range of quick hitch brackets click here

Unfortunately a high number of all accidents investigated on excavators can be assigned to the bucket detaching from the quick hitch brackets and injuring a ground worker. When this occurs the injuries are primarily fatal and major injuries. Be aware there may be many more dangerous occurrences that occur when a bucket detaches unintentionally from the hitch are not be reported and where no injury occurs

When inspecting quick hitch brackets inspectors should ask the following questions

- Ask site supervision if the QHs on the excavators under their control require a manual safety pin (they should know)

Is the risk of bucket detachment covered by their risk assessment? - In addition to evidence of training in operating the excavator, have excavator operators been trained in the use of their Quick hitch brackets and, where appropriate, in the use of the excavator as a crane?

- Is there a checklist in the cab of daily and weekly inspection and maintenance carried out on the excavator, and does this checklist include a check of the QH and lubrication as appropriate?

- Is there a record of the inspection and maintenance actually carried out?

- What are their management systems for checking whether manual safety pins are always in place?

- Whether the safety pins are inserted where appropriate. (If the pin is missing, try looking behind the driver’s seat!)

- Can the operator explain the type of QH system they have (do they know whether it needs a safety pin or not?) and is a manual or instruction card available in the cab?