Spiral Conveyor

Manufactured by Wrightfield Ltd

Product Buying Options

Product Capacity: One per week

Minimum Order Quantity: One

Additional Sales Information: All Spiral Conveyors are made to a customers exact specification so that they are perfectly suited to the products, throughput and handling method. Visit our factory and showroom and discuss with our design team call +44(0) 1379 872800

Product Description

Spiral Conveyors – Incline and Decline

Spiral conveyors are an effective way to transport products, items, or boxes between floors. They are sometimes called corkscrew conveyors or vertical conveyors as they use a conveyor belt to take the items up and down between levels. Spiral conveyors offer two key advantages –

Great at saving space and they’re

Ideal to accumulate and merge product lines.

If you are looking for a spiral conveyor as a standalone unit or as part of a conveyor system then the Wrightfield design team will work with your ideas and help design a solution to work with your needs call them on 01379 872800

The advantages of Spiral conveyors compared to traditional vertical belt conveyor systems are the space saving they [provide and there ability to merge and accumulate products.

Space saving

A spiral decline and incline conveyor occupies less floor space than a traditional belt conveyor, whilst performing the same function. When production, operation, factory or warehouse floor space is limited they can provide a useful solution. When floor space is expensive they can provide tangible cost savings to a business.

Merging

An important benefit of incline and decline spiral conveyor is the merging of products on multiple levels during the picking process into a single line for packing

Accumulation

With an accumulating spiral incline and decline conveyor, accumulation of products prior to processing or packaging is possible The spiral conveyor can be configured to hold products in distinct, independently controlled zones; allowing buffering between different processes.

There are various types of spiral incline and decline conveyors to meet your production, factory and warehousing needs:

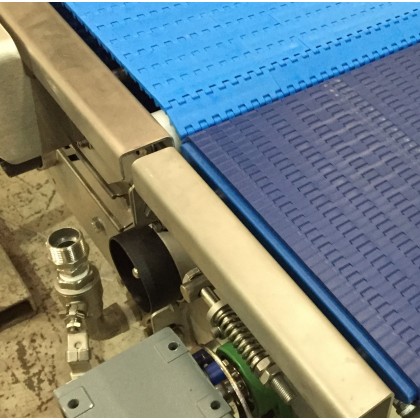

Continuous chain-slat spiral incline decline conveyors – A continuous chain-slat is controlled by a single drive unit. Easily installed and operated these conveyors provide a reliable method of transporting goods from one level to the next within a warehouse.

Helix belt spiral decline and incline conveyors – These provide the reliability of the simpler continuous chain-slat conveyor, with the addition of an accumulation feature. Typically comprising of ninety and one hundred and eighty degree conveyor sections belted together. Each section benefits from an independent drive, facilitating product accumulation.

Dual lane spiral incline and decline conveyor – This allows two product lines to be elevated, whilst attached to a singular central column, providing a cost and space saving solution.

When considering a spiral incline and decline conveyor there are different in and out configurations to meet your specific needs. Wrightfield will help you decide on the best configuration for your operation.

For information on Conveyor Systems click here . For information on other Stainless Steel products manufactured by Wrightfield Click Here